The Role of IoT Devices in Warehouse Monitoring

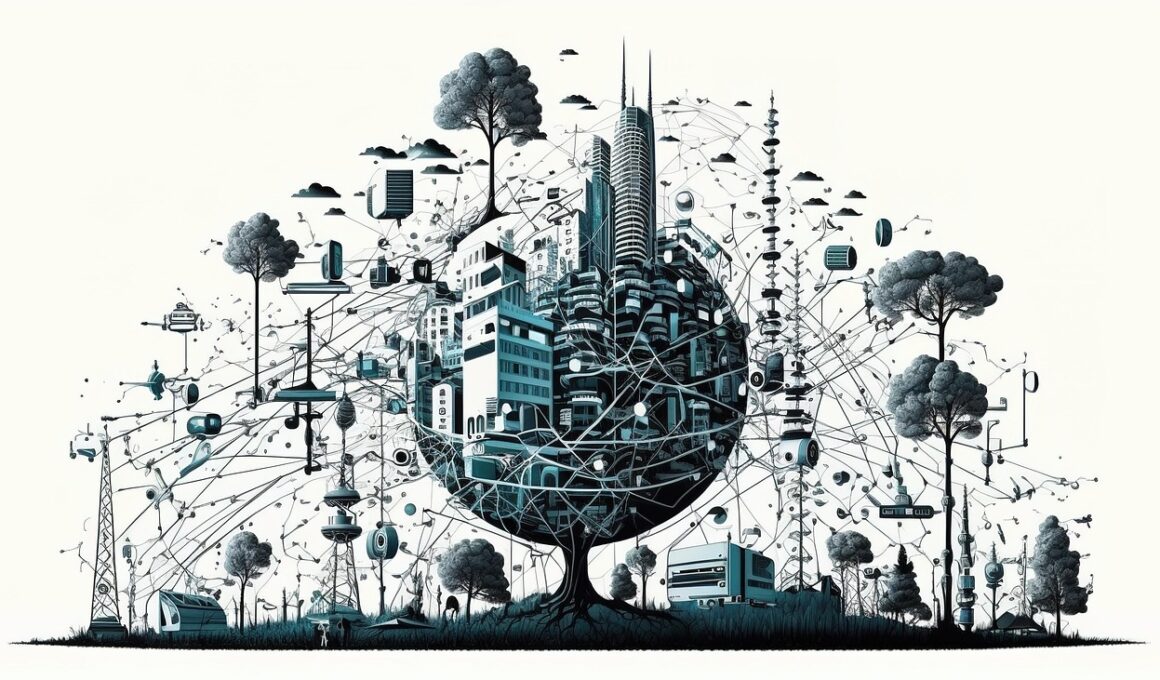

The traditional methods of warehouse management often struggle with inefficiencies that can result in increased costs and misplaced inventory. In recent years, the integration of Internet of Things (IoT) devices has revolutionized this field, allowing for real-time data collection and analysis. With IoT sensors, warehouses can monitor temperature, humidity, and even item location, thereby reducing losses and streamlining processes. This data-driven approach enables managers to make informed decisions quickly, resulting in a more agile supply chain. Additionally, IoT devices can facilitate easier tracking of inventory levels, ensuring that stock is replenished just in time. This not only minimizes storage costs but also reduces the risk of stockouts. Moreover, IoT solutions offer visibility across the entire supply chain, which enhances collaboration and accuracy. As warehouses become more digitized, the reliance on IoT technology will increase, pushing companies to adapt. Embracing these innovations positions businesses at the forefront of the competitive landscape, driving efficiency and customer satisfaction. Quite simply, IoT in warehouse monitoring is not just an option; it’s a necessity for success in today’s fast-paced market.

IoT devices have a significant impact on various aspects of warehouse operations. For instance, RFID tags and sensors are now commonplace. These devices automate stock tracking, reducing the need for manual checks and possible errors. IoT technologies provide real-time updates on product movement, which means warehouse managers can easily identify and locate items within vast storage areas. In addition to inventory management, IoT devices enhance safety conditions by monitoring environmental variables. Temperature-sensitive products require specific conditions, and sensors can alert staff if those conditions change. Furthermore, predictive analytics can utilize the data collected by IoT devices to forecast demand, thereby optimizing stock levels and ensuring timely deliveries. By utilizing this technology, businesses can adapt to fluctuations in demand, create more efficient workflow patterns, and maintain a clean database of all transactions. Moreover, communication between devices allows for smoother operations; for example, forklifts equipped with IoT can alert workers about their availability or required maintenance. Overall, the thoughtful integration of IoT into the supply chain ensures a substantial competitive edge.

Cloud Connectivity and Data Management

One key aspect of integrating IoT devices into warehouse management is leveraging cloud connectivity. By collecting and storing data in the cloud, businesses gain access to advanced analytics tools that can aid in decision-making processes. Cloud-based platforms enable real-time data exchange and synchronization across multiple locations. This capability allows businesses to monitor their supply chain performance at any level, making necessary adjustments for optimal efficiency. Moreover, cloud solutions minimize the risks associated with data loss, as data is securely stored offsite. Analytics derived from this information can provide insights into inventory turnover rates, seasonal trends, and even customer preferences. Consequently, companies can tailor their stocking strategies based on factual data rather than guesswork. Additionally, cloud connectivity fosters collaboration among different departments within an organization. Marketing, sales, and logistics teams can share insights promptly, aligning their efforts for maximum output. As organizations increasingly rely on data to drive results, the synergy between IoT devices and cloud technology becomes crucial for success in warehouse management and broader supply chain operations.

Asset tracking, facilitated by IoT, is another significant advantage regarding warehouse management. Traditional asset tracking methods often involved labor-intensive processes, such as manual logging and physical checks. Now, with IoT devices, companies can utilize GPS-laden assets that transmit their location continuously. This provides managers with a comprehensive view of their assets and surrounds significant improvements in accountability and loss prevention. For instance, if an item goes missing, it can be quickly located using the real-time data available through these devices. In addition to improving asset locatability, IoT devices can also provide information on the condition of goods. Sensors can detect if items are exposed to potentially damaging conditions, such as excessive temperature or moisture. This capability not only safeguards the goods but also increases customer trust since they receive products that meet quality standards. Moreover, better asset management directly correlates with improved inventory turnover rates, which translates to increased revenue. Hence, investment in IoT asset tracking systems contributes to the overall health of warehouse management.

Cost Reduction and Improved Efficiency

Adopting efficient IoT technologies fosters considerable cost savings for warehouses. The ability to analyze and optimize operations based on collected data allows companies to identify bottlenecks and areas for improvement. For instance, real-time monitoring significantly reduces operational inefficiencies by determining when equipment requires maintenance or replacement. This proactive approach helps avoid costly downtime and extends equipment lifespan. Additionally, streamlined inventory management can lead to reduced labor costs. By minimizing manual oversight, workers can be redirected to value-adding activities, thereby increasing overall productivity. Another area of cost reduction arises from reduced waste—by monitoring perishables and optimizing stock levels based on analytics; organizations can avoid overstocking and minimize losses. Furthermore, transportation costs can be reduced through improved logistics and route planning based on real-time data. Tracking shipments with IoT devices can minimize delays, ensuring timely deliveries to customers. By aligning resources efficiently, companies can significantly improve their profit margins. Overall, investing in IoT technology boosts operational efficiency while driving costs down, crucial for competitive advantage.

Another important benefit of IoT in warehouse management is enhanced customer satisfaction. When inventory is accurately tracked and managed, the likelihood of stock-outs is minimized. Customers appreciate the assurance that products will be available when needed, directly impacting their satisfaction rates. Additionally, real-time updates allow companies to provide better service delivery, giving customers precise information regarding their orders. Timeliness reflects commitment to service, which strengthens customer relationships. IoT technologies also enable personalized services based on customer data analysis. By understanding buying patterns, businesses can offer tailored recommendations or promotions, which enhances the overall customer experience. Furthermore, the tracking capabilities help ensure that deliveries are accurate and prompt, decreasing the likelihood of returns due to errors. Product quality is upheld through constant monitoring, ensuring customers receive items that meet their expectations. As businesses shift focus toward improving customer relationships, leveraging IoT technologies helps maintain competitive advantages by enhancing overall satisfaction and loyalty. In summary, the role of IoT devices in warehouse management significantly impacts not only operational efficiency but, more importantly, customer delight.

Future Trends

Looking forward, the future of warehouse management will be heavily intertwined with advancements in IoT technologies. As more businesses adopt smart warehouses, the trend toward automation will continue to grow. The integration with AI and machine learning will elevate the capabilities of IoT devices, enabling predictive maintenance and sophisticated demand forecasting. Furthermore, advancements in IoT security will help address potential vulnerabilities, allowing warehouses to feel more secure in adopting these technologies. The continuous evolution of the IoT ecosystem means that new devices and applications will emerge, offering even greater levels of efficiency and connectivity. Future innovations could also include more advanced robotics which work alongside IoT systems to streamline operations even further. The key to staying competitive will be the ability to adapt and implement these ensuing technologies effectively. Moreover, regulatory frameworks surrounding data protection will play a crucial role as businesses seek to optimize logistics while safeguarding customer information. Overall, the investment in IoT devices for warehouse management illustrates a commitment to embracing the digital age, paving the way for future achievements and transformations in supply chain dynamics.

In conclusion, IoT devices serve as a critical enabler in modern warehouse management. By providing real-time data capabilities, they significantly improve operations, customer satisfaction, and overall efficiency. With enhanced inventory tracking, cloud-based analytics, and reduced costs, businesses stand to gain substantial competitive advantages by leveraging IoT technology. Furthermore, as consumer expectations continue to evolve, remaining agile and responsive becomes increasingly important. Companies that invest in IoT will not only improve their operational processes but will also foster stronger relationships with their customers. The insightful data provided by these devices will help shape future trends in logistics and supply chain management. Embracing technological advancements such as IoT will drive businesses toward innovation, sustainability, and enhanced profitability. Ultimately, harnessing the power of IoT in warehouse management is not merely an option; it is necessary for thriving in today’s ever-changing market landscape. As we move forward, the ongoing collaboration between IoT solutions and warehouse operations will illuminate pathways toward efficiency, reliability, and customer engagement.