Balancing Cost and Resilience in Supply Chain Decisions

In today’s ever-evolving global marketplace, businesses face relentless challenges including supply chain disruptions that can lead to significant financial losses. Businesses must adopt effective strategies that balance cost-control and resilience in their supply chains. Understanding the dynamics of supply chain management is crucial in maintaining operational excellence and leveraging competitive advantage. By optimizing both costs and resilience, management can ensure that their organizations remain agile and responsive in the face of unexpected events. Companies must analyze their supply chains comprehensively to identify weaknesses and potential points of failure that could exacerbate future disruptions. By incorporating flexible sourcing strategies, businesses can reduce reliance on single suppliers and enhance their capacity to adapt quickly to market changes. Additionally, investing in technology can provide valuable insights, enabling organizations to predict potential disruptions and react effectively. This dual approach encourages transparency throughout the supply chain, allowing stakeholders to collaborate on strategies that mitigate risks. Ultimately, the goal is to maintain a balance between minimizing costs and enhancing the resilience needed to withstand and recover from disruptions effectively.

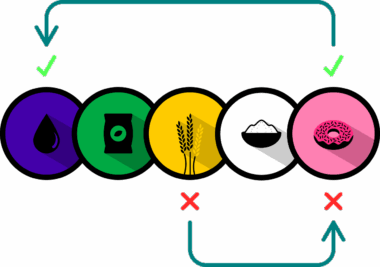

As businesses strive for enhanced resilience while managing costs, it becomes increasingly essential to prioritize risk management strategies in supply chain decision-making. Risk assessment should encompass various factors, including geopolitical dynamics, economic volatility, and environmental sustainability. By conducting thorough risk assessments, organizations can classify potential risks and implement tailored strategies to address them. This proactive approach can not only mitigate disruptions but also foster innovation within the supply chain process. For instance, the introduction of smart technologies and data analytics facilitates real-time monitoring of supply chain operations, providing valuable insights. These insights empower businesses to make informed decisions and optimize their resource allocations effectively. Diversifying suppliers and geographical sourcing also plays a crucial role in minimizing vulnerabilities. Reliance on a single supplier or region can constrain a company’s ability to respond to disruptive events. Moreover, flexibility in manufacturing processes can be enhanced by adopting modular production techniques, allowing for easier adaptation to demand fluctuations. Through these comprehensive measures, organizations can strategically align their resources, navigating the complexities of supply chain management with informed precision.

Leveraging Technology for Supply Chain Resilience

Leveraging cutting-edge technologies is fundamental to achieving success in balancing cost and resilience in supply chains. Technologies such as artificial intelligence, machine learning, and data analytics make it possible to forecast demand precisely and adjust supply levels accordingly. These innovations enhance visibility across the supply chain, allowing for quicker identification of potential disruptions. Integrating these technologies ensures that all stakeholders can access and share data in real-time, paving the way for collaborative decision-making processes. As companies respond to disruptions, they can utilize simulation software to model various scenarios, evaluating how different strategies would impact their operations. This not only aids in immediate responses but also helps refine long-term strategies that promote resilience. Moreover, blockchain technology offers enhanced traceability and transparency, as it allows each transaction or change in the supply chain to be securely recorded. By establishing trust among stakeholders, businesses can foster stronger relationships that ultimately lead to more robust supply chains. Embracing these technologies not only mitigates risks but also provides opportunities for efficiency and cost reduction in supply chain management.

Supply chain disruptions often result from unexpected events, but organizations need to engage in proactive risk management to minimize such occurrences. Crafting a comprehensive risk management plan addresses vulnerabilities while aligning with strategic business goals. Risk mitigation should be a continuous and evolving process wherein companies regularly reassess their supply chain environment. This involves establishing key performance indicators (KPIs) to measure resilience over time, allowing for adjustments as needed. Additionally, fostering strong relationships with stakeholders is paramount in ensuring a reliable supply chain during disruptions. Collaborating with suppliers, customers, and logistics partners can clarify each stakeholder’s role in crisis scenarios. Active communication ensures that everyone is adequately prepared, leveraging shared resources to respond more efficiently. Furthermore, engaging in scenario planning can also bolster how an organization reacts to unforeseen events. Senior leadership must involve all relevant departments in the planning stages, fostering a collective understanding of processes required for effective crisis response. By embedding resilience into company culture, businesses build better infrastructures that can withstand and adapt to challenges in supply chain dynamics.

Investing in Human Capital

Investing in human capital is equally critical when outlining strategies for effective supply chain disruption management. Human resources are the backbone of any organization, and equipping employees with the skills necessary to navigate difficult situations can greatly enhance resilience. Training programs focused on supply chain management provide employees with essential knowledge of the processes and technologies utilized. Empowering employees to make real-time decisions during disruptions can lead to quicker, more effective responses. Furthermore, cross-training personnel across various functions ensures that teams remain agile and informed in crisis situations, facilitating smoother operations. Cultivating a culture of continuous learning helps integrate innovative ideas into supply chain management processes. Regular workshops and training sessions can provide opportunities for employees to collaborate, share experiences, and refine problem-solving skills. Additionally, employee empowerment fosters a sense of ownership and responsibility, making teams more proactive in addressing potential threats. By investing in their workforce, organizations can develop a resilient and adaptable supply chain capable of navigating the complexities of today’s business environment while maintaining cost-effectiveness.

The integration of sustainable practices within supply chain management offers significant benefits beyond resilience and cost control. Sustainable supply chains not only reduce environmental impact but also contribute to long-term financial performance by establishing brand loyalty among eco-conscious consumers. Companies are increasingly prioritizing sustainability initiatives, recognizing that environmentally responsible practices enhance reputation and customer trust. Incorporating sustainable sourcing and transparent labor practices within the supply chain builds greater brand value while ensuring alignment with ethical standards. Additionally, exploring alternative materials and processes can lead to efficiency gains, supporting cost-optimization strategies. Collaboration with suppliers who prioritize sustainability aids in reinforcing shared goals, creating synergies that benefit all stakeholders involved. By adopting a circular economy approach, businesses can further reduce waste and maximize resource utilization, creating a sustainable framework for future growth. Moreover, leaders must communicate their commitment to sustainability internally and externally, inspiring a culture that values environmental responsibility. By harmonizing cost and sustainability, organizations can foster a more resilient supply chain, resonating with customers and stakeholders who demand ethical and sustainable practices across all business domains.

Future Trends in Supply Chain Management

Anticipating future trends in supply chain management is essential for navigating upcoming challenges and opportunities. The increasing complexity and globalization of supply chains necessitate innovative approaches to maintain resilience and cost-effectiveness. Digital transformation is a trend that will continue to dominate supply chain dynamics, with businesses adopting advanced technologies to enhance efficiency. Furthermore, sustainability initiatives are expected to drive supply chain planning, influencing suppliers to adopt environmentally friendly practices while minimizing costs. The emergence of the Internet of Things (IoT) will accelerate how organizations monitor supply chain operations, allowing for enhanced data collection and analytics capabilities. These advanced capabilities enable more informed decision-making, leading to improved responsiveness to disruptions. Additionally, consumer behavior is continuously evolving, prompting the need for agile supply chains that can adapt quickly to changing preferences. Organizations may shift towards more localized supply chains to reduce transportation costs while ensuring faster delivery times. Overall, staying ahead of these trends is vital for businesses aiming to thrive in a competitive landscape, ensuring that cost and resilience remain complementary objectives in their supply chain strategies.

The integration of sustainability within supply chain strategies not only ensures resilience but also aligns with consumer demands. As customers increasingly advocate for eco-friendly practices, companies must respond strategically. Aligning supply chain operations with sustainable frameworks creates competitive advantage while fostering brand loyalty. Moreover, businesses that prioritize sustainability often realize cost savings through increased efficiency and waste reduction. The key lies in redefining supply chain metrics to encompass both environmental impact and cost-effectiveness. Using a lifecycle assessment approach allows organizations to evaluate their supply chain’s ecological footprint comprehensively. This not only identifies areas for improvement but also informs better decision-making processes. Furthermore, engaging stakeholders in sustainability goals fosters collaboration and shared responsibility across the supply chain. Effective communication of these goals to customers can enhance brand equity as eco-conscious consumers make informed purchase choices. Organizations that invest in sustainable practices will not only remain competitive but also contribute positively to societal challenges. Ultimately, by assessing risks, investing in technology, and embracing sustainable practices, companies can create supply chains that are resilient and responsive to future disruptions.