Role of Demand Sensing in Modern Supply Chain Management

In today’s dynamic marketplace, demand forecasting has emerged as a critical component for efficient supply chain management. Organizations increasingly leverage data analytics and advanced technologies, such as artificial intelligence and machine learning, to predict customer demands accurately. Effective demand forecasting enables businesses to align their inventory levels with market needs, reducing excess stock and minimizing stockouts. Consequently, companies can optimize their supply chain processes, reduce costs, and enhance customer satisfaction. In this context, demand sensing plays a pivotal role in accurately interpreting market signals and trends, contributing to improved forecast accuracy. It involves gathering real-time data from various sources, including sales patterns, customer behavior, and even social media trends, to generate reliable demand insights. By utilizing demand sensing techniques, organizations can respond promptly to changing market conditions, ensuring they maintain a competitive edge. This proactive approach not only helps in identifying potential demand spikes or drops but also allows businesses to make informed decisions regarding procurement and distribution. In essence, demand sensing empowers companies to navigate the complexities of modern supply chains effectively.

The implications of demand sensing extend beyond merely optimizing inventory levels; it also strategically impacts supplier relationships. By having a clearer understanding of demand fluctuations, organizations can better communicate with their suppliers, ensuring that they are well-prepared to meet changing needs. Enhanced collaboration with suppliers leads to improved service levels, reducing lead times and ensuring that products are available when and where they are needed. Additionally, effective demand sensing contributes to financial optimization. With a more accurate understanding of future demand, companies can allocate resources more efficiently and invest in areas that promise the highest returns. This approach reduces waste and maximizes profit margins, further solidifying an organization’s position in the marketplace. Furthermore, demand sensing fosters agility within supply chain networks. Companies can swiftly adjust their production schedules and logistics to respond to demand changes, minimizing disruptions. Such flexibility is vital in today’s ever-changing business environment, where consumer preferences can shift rapidly. In conclusion, integrating demand sensing into supply chain strategies not only helps businesses to forecast demand accurately but also enhances their overall operational efficiency.

Technological Advancements in Demand Sensing

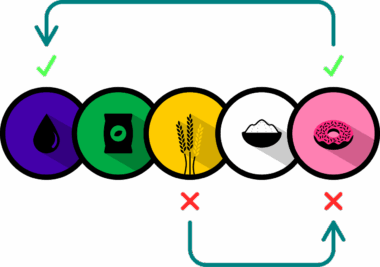

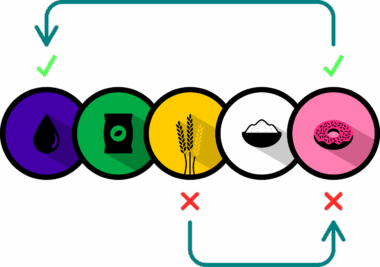

The integration of technology into demand sensing processes defines modern supply chains. Advanced analytics platforms, powered by big data, enable organizations to track and analyze vast amounts of data efficiently. Machine learning algorithms utilize historical data to identify patterns, while real-time analytics provides insights that reflect current market dynamics. Such technological advancements allow businesses to anticipate shifts in consumer demand proactively. These insights contribute to establishing better inventory management practices, minimizing instances of stockouts or overproduction. Moreover, automation in data collection contributes to increased accuracy in demand sensing. Fewer manual processes reduce the likelihood of errors, ensuring companies base their decisions on reliable data. Furthermore, cloud computing facilitates seamless data sharing between supply chain partners, creating a cohesive ecosystem. With each player in the supply chain contributing data, organizations achieve a holistic view of demand trends. This collaborative approach not only enhances forecasting accuracy but also fosters innovation and responsiveness. Ultimately, the utilization of technology in demand sensing allows businesses to mitigate risks, capitalize on emerging opportunities, and drive growth in an increasingly competitive landscape.

An essential component of effective demand sensing is the ongoing training and development of personnel involved in the supply chain. As technologies evolve, keeping teams updated with the latest tools and techniques becomes imperative. Organizations must invest in training programs to ensure that their employees can interpret data accurately and leverage insights effectively. This human element cannot be overlooked; even the most sophisticated tools are only as effective as the people using them. Encouraging a data-driven culture involves empowering employees to engage in continuous learning and adaptation to changing technology trends. Additionally, fostering collaboration among various departments enhances the overall effectiveness of demand sensing efforts. This collaboration allows for a unified approach to data analysis, ensuring that inputs from various sources are considered in demand forecasting. Recommendations stemming from different teams can lead to richer insights. Enhanced communication fosters a deeper understanding of consumer trends and preferences. Consequently, aligning sales, marketing, and supply chain strategies leads to a more agile and responsive organization. In summary, investing in talent development is crucial for maximizing the potential of demand sensing in supply chain management.

Challenges in Implementing Demand Sensing

Despite its benefits, implementing demand sensing is not without challenges. One significant hurdle companies face is data integration. Organizations often operate in silos, with information scattered across various departments, leading to discrepancies in data quality and availability. Overcoming these silos requires effective communication and common data-sharing strategies among stakeholders. Furthermore, organizations must address data privacy and security concerns, particularly when handling sensitive customer information. Ensuring compliance with regulations while utilizing customer data effectively presents a dual challenge for companies engaging in demand sensing. Another obstacle is resistance to change within the organization. Employees accustomed to traditional demand forecasting methods may be hesitant to adopt new technologies. Leaders must provide clear communication about the rationale behind adopting demand sensing and its potential benefits. Additionally, organizations may face issues regarding the adoption of new technology. Choosing appropriate tools that align with the company’s existing infrastructure can be daunting. The complexity of the technology landscape necessitates thorough research and testing to find optimal solutions. Overall, understanding these challenges enables organizations to develop effective strategies for successful demand sensing implementation.

In addressing the complexities of demand sensing, organizations need to articulate a clear vision and strategy for implementation. This involves outlining specific goals, setting realistic expectations, and defining key performance indicators (KPIs) that will gauge success. By establishing a well-defined framework, companies can systematically approach the integration of demand sensing into their supply chain management processes. Regular monitoring and evaluation of KPIs can provide valuable insights into the effectiveness of the demand sensing strategy, allowing for necessary adjustments. Additionally, leadership buy-in is essential to foster a culture that embraces data-driven decision-making. Engaging senior management in the development and communication of this vision encourages alignment throughout the organization. It’s crucial to ensure that all team members understand the significance of demand sensing and how it fits into the broader supply chain strategy. Implementing a phased approach to integration can also mitigate risks and allow for iterative learning. Organizations can pilot demand sensing initiatives in selected areas before a full rollout, providing opportunities to identify and rectify issues that arise. This methodical approach ultimately enhances the likelihood of successful demand sensing implementation.

Future of Demand Sensing in Supply Chain

The future of demand sensing in supply chain management holds promising potential as organizations continue to harness innovative technologies. The growing utilization of artificial intelligence and predictive analytics will further enhance the precision of demand forecasts. Companies are expected to increasingly rely on machine learning algorithms that not only analyze historical data but also adapt based on real-time trends and patterns. With advancements in Internet of Things (IoT) technology, real-time data acquisition will become even more sophisticated, enabling organizations to capture consumer behavior and preferences dynamically. As these trends evolve, demand sensing will become more integrated with overall supply chain strategies, impacting decision-making processes at every level. Moreover, the integration of blockchain technology has the potential to improve transparency and trust within supply chains. Enhanced traceability of data ensures that decision-makers can rely on accurate information when implementing demand sensing techniques. Additionally, as sustainability becomes a primary concern, demand sensing methodologies will incorporate environmental factors into forecasting models, aligning operation practices with consumer expectations. Ultimately, organizations that embrace these innovative technologies will enhance their agility and resilience in the face of market fluctuations.

In conclusion, the role of demand sensing in modern supply chain management cannot be overstated. As organizations strive to enhance their operational efficiency and responsiveness to market fluctuations, demand sensing emerges as a vital tool in their arsenal. Effectively implemented, it allows for better alignment between inventory levels and actual market demand, thereby optimizing resources and reducing costs. Furthermore, as technology continues to advance, the sophistication of demand sensing methodologies will increase, providing even greater accuracy and insights. The challenges associated with data integration, privacy concerns, and resistance to change must be addressed to fully realize the benefits of this approach. Continuous investment in training staff and fostering a data-driven culture will be essential in overcoming these barriers. Leaders must articulate a clear strategy for demand sensing that aligns with the organization’s goals, ensuring buy-in at all levels. The future of demand sensing promises exciting advancements as businesses integrate emerging technologies and adapt to evolving consumer preferences. By embracing this proactive approach, organizations can position themselves for success in an increasingly competitive marketplace.