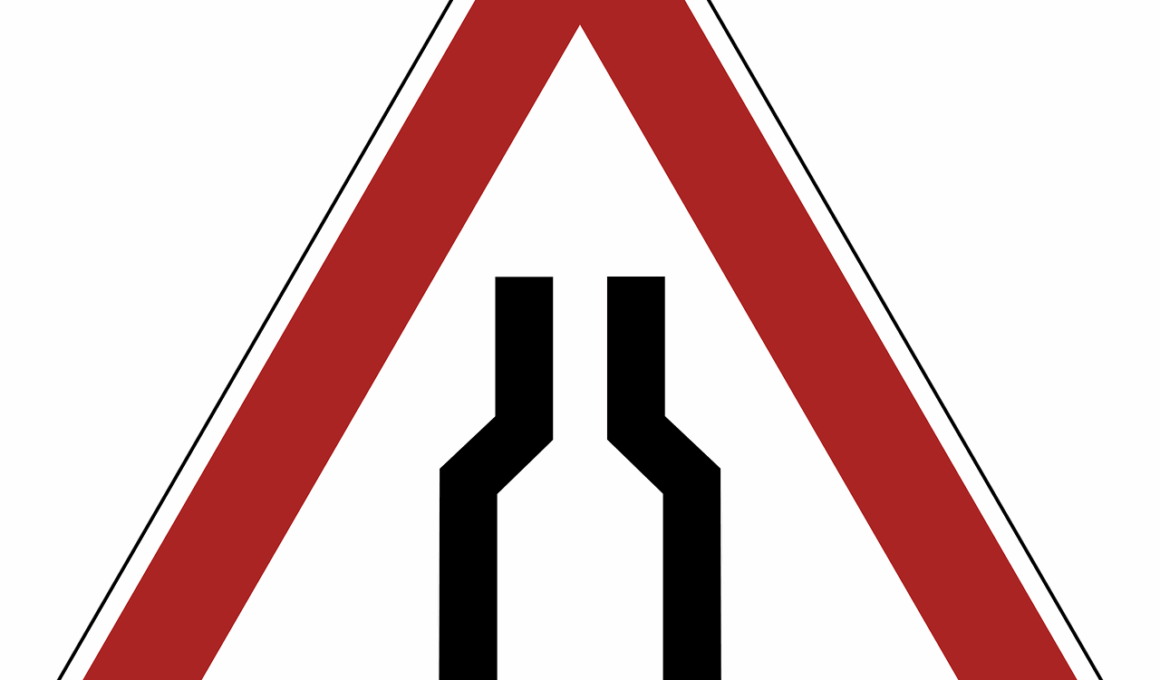

Understanding Bottleneck Analysis in Operations Management

Bottleneck analysis is crucial for improving efficiency in operations management. It is a systematic approach used to identify the limiting factors that hinder workflow processes. The bottlenecks can occur in any stage of production, impacting overall performance. By recognizing these constraints, organizations can prioritize resources to alleviate barriers. Key methods include data collection, process mapping, and statistical analysis. Data-driven insights help to determine where delays occur and identify blockages. This proactive approach is vital in various industries like manufacturing, service delivery, and supply chain management. Implementing changes based on this analysis can lead to enhanced throughput and reduced operational costs. Moreover, regular review and revisions of workflows are essential as processes evolve. Different tools, such as the Theory of Constraints (TOC), provide structured guidance. By focusing efforts on resolving these bottlenecks, organizations can ensure smooth operation. Continuous monitoring and assessment create room for growth and improved responses to emergent demands. Companies can build a resilient operation that adapts effectively to shifting market conditions through strategic bottleneck resolution.

Importance of Identifying Bottlenecks

The primary goal of bottleneck analysis is improving efficiency and productivity. Identifying bottlenecks ensures that resources, including time, materials, and labor, are allocated effectively. When organizations fail to recognize these constraints, time and money can be wasted on optimizing processes that do not yield results. Additionally, recognizing bottlenecks allows for targeted interventions that have the highest impact. By focusing on the weak links within a process chain, managers can implement improvements that facilitate smoother operations. This strategic focus enhances employee satisfaction and better serves customers who rely on timely deliveries. Organizations can avoid disruptions in workflows and maintain competitive advantage by addressing bottlenecks decisively. In the long run, this benefits overall organizational strategy and performance. Companies that continuously monitor for bottlenecks are better equipped to handle unexpected challenges. This agility is not only crucial for sustaining operations but also for fostering innovation and growth. Incorporating continuous improvement processes creates a system where bottleneck analysis is a regular practice. Ultimately, the awareness and understanding of these weak points lay the foundation for long-term success.

Bottleneck analysis can be applied across various operational scenarios, from manufacturing to service sectors. In the manufacturing domain, assembly lines are often the focal point for such analysis. Each stage of production must work harmoniously, without delays or inefficiencies. By identifying where slowdowns occur in production lines, managers can implement changes to streamline these operations. Techniques like time-motion studies can be beneficial in understanding worker efficiency. Additionally, in service industries, bottlenecks may appear in customer service operations or administrative procedures. For example, long wait times in call centers can be investigated through bottleneck analysis. Technological solutions such as automation and better scheduling can be proposed, reducing workloads on specific roles. In both cases, effective root cause analysis can isolate the issues that contribute to bottlenecks. Furthermore, cross-training employees ensures versatility, allowing flexibility in handling operational peaks. Organizations that embrace versatility can effectively manage varying demand levels while minimizing bottlenecks. By ensuring all areas are optimized, they create comprehensive strategies that promote operational success. A proactive approach towards addressing bottlenecks leads to maximized productivity and a happier workforce.

Bottleneck resolution requires careful planning and implementation strategies to ensure sustainability. Transitioning from identifying a bottleneck to resolving it can be complex. Therefore, stakeholders should be involved in developing a comprehensive action plan. A well-defined approach helps maintain accountability and facilitates smoother transitions. Communication among departments is essential to implement effective solutions without disrupting the existing workflow. Training sessions may be necessary to equip employees with the skills needed to adapt to new processes. Moreover, systems should be put in place to monitor progress continuously. This ensures that the steps taken effectively address the initial bottleneck identified. Frequent reviews of the performance metrics will allow for quick adjustments if needed. More importantly, fostering an open environment for feedback can encourage employees to share insights about persistent issues. By doing this, organizations can keep the lines of communication open, improving morale. Additionally, documenting the entire process aids in future bottleneck identification. As the organization grows, new bottlenecks will inevitably occur, and having a foundation for analysis can expedite future problem-solving efforts. Therefore, overall engagement in the bottleneck resolution process is essential for sustained improvement.

Using Technology for Bottleneck Analysis

In modern operations management, incorporating technology into the bottleneck analysis process has proven invaluable. Advanced software tools enable organizations to visualize workflows in real-time, making it easier to identify critical issues. Data analytics provide insights into operational metrics, helping pinpoint trends leading to bottlenecks. Technologies such as Artificial Intelligence (AI) and Machine Learning (ML) aid in predicting potential bottlenecks based on historical data. By simulating various scenarios, organizations can proactively prepare for fluctuations in demand. This anticipatory approach makes it possible to alleviate bottlenecks before they can develop into significant problems. Tools like flowchart software can map out processes effectively, highlighting inefficient areas that require attention. Furthermore, using digital twin technology allows organizations to create virtual representations of their operations, identifying points of congestion before implementing changes. Investment in technology streamlines the identification process and contributes to improved accuracy. Ultimately, organizations that leverage technology can operate with enhanced agility. This capability allows for adjustments tailored to the changing dynamics of the market and provides greater visibility into operations for better strategic planning.

Continuous improvement is a vital mindset in operations management, particularly when addressing bottleneck issues. Recognizing that bottlenecks are inherent in any process requires a commitment to regularly evaluate efficiency. The philosophy of Kaizen emphasizes making small, incremental changes that collectively lead to significant improvements. By adopting this philosophy, organizations can focus on ongoing refinement of their processes. Teams should be encouraged to regularly assess their performance against established benchmarks. Identifying patterns of inefficiency enables organizations to address underlying causes. Additionally, fostering a culture of innovation encourages employees to contribute ideas that can help alleviate bottlenecks. Involving staff in identifying and resolving bottlenecks builds ownership and accountability. Continuous improvement also involves using customer feedback as a metric for identifying delays and addressing them directly. Organizations should be willing to adapt their processes and strategies based on external input. Establishing regular reviews of process performance ensures that teams remain aligned with organizational goals. Therefore, building a resilient operation that continuously seeks areas of improvement is necessary. This proactive stance toward bottlenecks transforms challenges into opportunities for growth.

Bottleneck analysis is not a one-time activity; it must be integrated into ongoing operational strategies. Monitoring key performance indicators (KPIs) related to bottlenecks is essential for sustained improvement. Organizations should implement regular intervals for analyzing processes to remain reactive to any inefficiencies. This ongoing assessment includes revisiting previous bottleneck locations to confirm whether improvements have endured. Having a standard methodology for analyzing bottlenecks allows consistent tracking of performance over time. Reports should be generated, highlighting both successes and areas needing further intervention. By periodically updating the status of previous bottlenecks, organizations can ensure they don’t resurface. Additionally, creating a feedback loop involving team members fosters an inclusive approach to problem-solving. Encouraging employees to share their observations and solutions can unearth fresh ideas for further optimization. Organizations that see bottleneck analysis as a part of their core operational process are likely to maintain a competitive edge. By incorporating cross-functional teams in this ongoing effort, the collective intelligence of diverse perspectives enhances overall decision-making. Ultimately, a long-term commitment to proactive bottleneck analysis ensures continuous development and improved operational efficiency.

Conclusion

In conclusion, understanding bottleneck analysis in operations management is crucial for improving operational efficiency. Through identifying, analyzing, and addressing bottlenecks, organizations can optimize their workflows. This process results in reduced costs, improved productivity, and enhanced customer satisfaction. A robust approach involving technology and continuous improvement leads to sustainable success. Moreover, a culture of transparency and collaboration empowers employees to contribute to problem-solving. Integrating bottleneck analysis into daily operations creates an organizational mindset focused on maximization. Ultimately, success hinges on the ability to effectively manage and address bottlenecks. As markets evolve, those who incorporate robust bottleneck analysis will adapt more effectively to new challenges. Organizations that embrace this strategic approach can expect improved operational performance and a healthier bottom line. Therefore, fostering a sense of responsibility among teams in recognizing and solving bottlenecks can be a game-changer. The commitment to consistent monitoring and evaluation solidifies the strategy’s success. Bolder steps can lead to increased operational agility and overall resilience in the long run. Thus, allocating resources to implement robust bottleneck analysis is essential for organizations committed to excellence. The benefits extend far beyond just efficiencies; they create a more dynamic, responsive operation.