Automation Innovations in Third-Party Logistics Warehousing

Third-party logistics (3PL) warehousing is undergoing a transformation due to advances in automation technologies. This shift includes the use of robotics, artificial intelligence, and comprehensive management software, which aim to streamline operations and reduce costs. Many 3PL providers are now investing heavily in these innovations to remain competitive and enhance operational efficiency. The integration of automated systems can minimize human error, speed up order fulfillment, and improve inventory accuracy. Moreover, automating repetitive tasks allows warehouse employees to focus on more strategic tasks, ultimately increasing productivity. Various solutions are available, including autonomous mobile robots (AMRs) that transport goods, automated storage and retrieval systems (AS/RS), and inventory management software that uses predictive analytics. These technologies not only boost operational speed but also positively impact customer satisfaction by increasing order accuracy and reducing delivery times. As customer demands evolve, 3PL providers must adapt their operations accordingly to maintain their relevance in the marketplace. The future of 3PL warehousing lies in companies embracing these advancements to thrive in a competitive landscape.

One major benefit of automation in 3PL warehousing is the enhanced visibility it provides throughout the supply chain process. By leveraging real-time data analytics, logistics managers can monitor inventory levels, track shipments, and acquire insights into potential disruptions. Automated systems can offer a 360-degree view of warehouse operations, which empowers decision-makers to respond swiftly to changes in demand or supply. For instance, cloud-based platforms enable centralized stock management by integrating data from different locations. This allows for optimized stock levels and reduces the risk of overstocking or stockouts. Furthermore, automation facilitates better communication among stakeholders, including suppliers, transportation companies, and retailers. Improved reporting capabilities mean that anomalies can be detected and addressed proactively, minimizing costs associated with inefficiencies. Enhanced visibility also translates to improved risk management and compliance with regulations. By automating these processes, 3PL providers can initiate more effective inventory practices that lead to lower costs and improved service levels. As businesses look for partners capable of managing their logistics more efficiently, the role of automated solutions becomes increasingly pivotal.

Reducing Labor Costs Through Automation

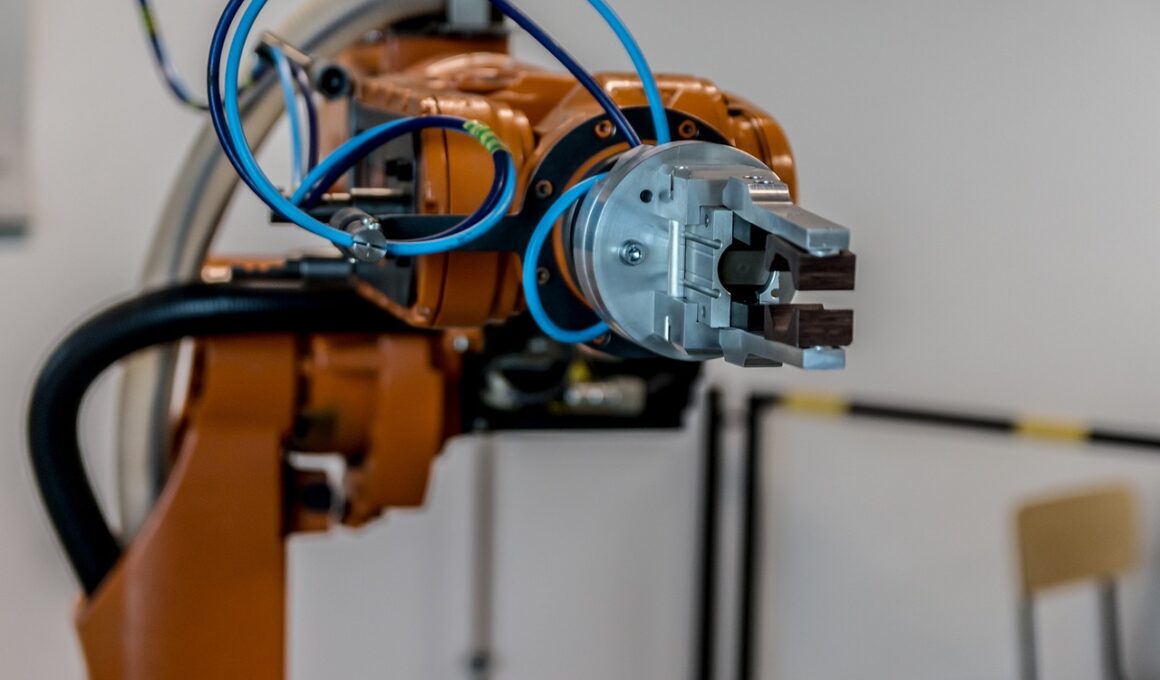

Automation in warehousing reduces labor costs significantly, a major concern for many 3PL providers. As wages continue to rise, labor shortages present challenges, so investing in automation can counteract these issues. Robotic systems can efficiently perform tasks such as picking, packing, and sorting, which traditionally required manual labor. By reducing reliance on human labor, companies can also mitigate risks associated with workplace injuries and health concerns. Increased automation leads to more consistent workflow management, which reduces human errors and improves safety protocols. For example, robotic pickers operate under specific programmed conditions, minimizing mistakes that human workers may inadvertently make. By integrating automated technologies, firms can deploy their human workforce strategically to areas that require emotional intelligence, creativity, or complex problem-solving skills. Additionally, the precise nature of automated systems allows for better scalability. As order volumes fluctuate, automation can quickly be adjusted to manage varying workloads without the need for extensive retraining or hiring. This not only stabilizes labor costs but also ensures the workforce remains agile in response to market demands.

Inventory management is another area where automation proves indispensable for third-party logistics providers. Traditional inventory control methods can be labor-intensive and error-prone, often resulting in discrepancies. Automated inventory management systems allow for real-time tracking of stock levels through RFID and barcode technologies. By improving accuracy in inventory records, these systems help in optimizing stock replenishment processes, minimizing both excess inventory and shortages. Furthermore, predictive analytics can guide the ordering process, giving managers insights into upcoming trends based on customer purchases and seasonal changes. This capability not only enhances the inventory turnover rate but also reduces storage costs associated with excess stock. Streamlined inventory management empowers businesses to make data-driven decisions that foster efficiency and business growth. Additionally, automation helps in managing returns more effectively, enhancing the customer experience. With automated systems in place, the time taken to process returns can be significantly cut down, allowing for quick inventory updates, thus maintaining higher customer satisfaction. Overall, investing in smart inventory management solutions brings forth scalability and accuracy, driving long-term profitability.

Integrating Artificial Intelligence for Enhanced Efficiency

Artificial intelligence (AI) is becoming a vital component in automating third-party logistics warehousing solutions. Through the utilization of AI-driven algorithms, 3PL providers can optimize routing, forecasting, and scheduling within their operations. AI technology enables predictive analytics which allows businesses to assess market trends and customer preferences effectively. This capability leads to better inventory management by assisting logistics managers in understanding which products are likely to perform well during specific times. Moreover, AI can analyze vast datasets to enhance warehouse layout planning, improving space utilization and operational efficiency. By implementing AI solutions, logistics managers can make informed decisions, resulting in optimized resource allocation. Furthermore, AI-driven robots can work alongside humans, further improving productivity and safety within warehouses. They assist with tasks such as inventory counts and order picking, reducing workloads and enhancing fulfillment speeds. Another significant benefit of AI integration is its ability to autonomously analyze operations for inefficiencies, helping 3PL providers continuously refine their processes. As technology and supplies become increasingly intertwined, integrating AI solutions is crucial for staying competitive in the logistics landscape.

Automation in third-party logistics warehousing also enhances overall sustainability initiatives. Many companies strive to reduce their carbon footprints and become more environmentally responsible, and automated systems play a key role in achieving these goals. Automated solutions such as optimal routing algorithms can significantly reduce fuel consumption during transportation by identifying the shortest or least congested routes. Moreover, warehouses can embrace energy-efficient practices inspired by automation, including automated lighting systems that activate only when necessary. These strategies not only contribute to a greener operation but also lead to substantial cost savings through energy reductions. Adding to sustainability, automated systems can also minimize waste during packing operations. By ensuring that only necessary materials are used for packaging, companies can lower the amount of recyclable materials used and contribute positively to waste management efforts. Furthermore, by incorporating eco-friendly technology, such as electric or hybrid vehicles in automated fleets, 3PL providers can further lessen their environmental impact. Overall, the integration of sustainability within automated systems is not just beneficial for the planet, but also positively influences brand reputation and customer loyalty.

Future Trends in 3PL Automation

Looking ahead, the future of automation in third-party logistics warehousing is filled with possibilities, driven by technological advancements. One trend gaining traction is the integration of the Internet of Things (IoT) into warehouse operations. IoT devices can provide real-time data on asset conditions, location, and status, thereby enhancing efficiencies even further. With connected devices, proactive supply chain management is achievable, as data can facilitate immediate decisions regarding inventory adjustments and supply chain disruptions. Another trend to observe is the rise of autonomous vehicles for transportation and delivery services. Robots and drones can fulfill last-mile delivery tasks more efficiently than traditional methods, resulting in reduced delivery times and costs. Moreover, collaborative robots or cobots are expected to become more prevalent, allowing workers and robots to coexist and share tasks in warehouses. This synergy fosters a more dynamic and responsive environment. Additionally, advancements in machine learning will enable more sophisticated predictive analytics that improve decision-making. As these trends unfold, 3PL providers must proactively adapt to technological shifts to remain competitive and address evolving consumer demands effectively.

In conclusion, the role of automation in third-party logistics warehousing is essential for meeting the complexities of modern supply chains. As 3PL providers face increasing pressure to maintain efficiency and reliability, investing in automation technologies becomes imperative. These innovations provide significant benefits, including cost savings, improved accuracy, and heightened customer satisfaction. Furthermore, as sustainability becomes a growing concern, automation also prepares firms to adopt greener practices that benefit the environment. As the logistics landscape evolves, those companies who prioritize automation will undoubtedly gain a competitive edge. The future promises even more remarkable advancements in technology that will further revolutionize warehousing operations. From AI integration to IoT devices, the potential for improved efficiency and innovation is vast. Moving forward, logistics providers must continually assess their operations, remain adaptable, and invest wisely in automation technologies. Embracing these changes will enable them to serve their clients effectively and enhance their market presence. Overall, the necessity for automation in supply chain management cannot be overstated, and businesses must prioritize their journey toward sophisticated and scalable solutions.