How to Use Historical Data for Demand Forecasting

Demand forecasting is crucial for effective supply chain management. Businesses leverage historical data to predict future demands, making informed decisions that can enhance efficiency. By analyzing past sales data, companies can identify patterns, trends, and influences that drive demand. A thorough understanding of seasonal fluctuations in consumer behavior is vital, as these factors can significantly impact inventory levels and supply management. Utilizing historical data allows businesses to fine-tune their stock levels, reducing costs incurred through overstock or stockouts. Additionally, forecasting based on previous sales cycles supports better planning and resource allocation. Identifying which products perform well during specific timeframes can help businesses optimize their marketing strategies and align production schedules. Implementing advanced analytical techniques, such as regression analysis and time-series forecasting models, can further enhance the accuracy of predictions. Businesses can also benefit from integrating multiple data sources, including market trends, economic indicators, and competitive analysis. By blending these insights with historical data, companies can create a comprehensive forecast that drives strategic decisions. Ultimately, effectively harnessing historical data unlocks opportunities for growth, improves customer satisfaction, and increases overall profitability.

The Importance of Data Quality

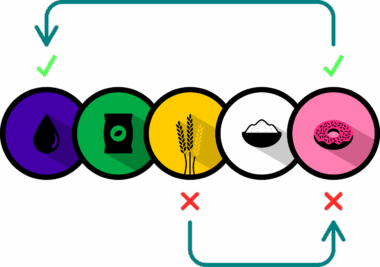

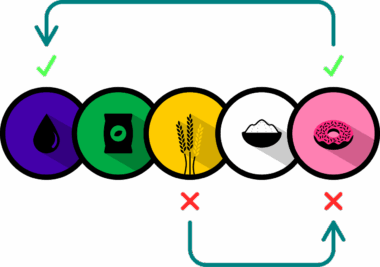

When using historical data for demand forecasting, the quality of the data is paramount. Poor data quality can lead to inaccurate predictions, ultimately affecting supply chain performance. Companies must ensure that their historical data is clean, consistent, and reliable. Data inaccuracies, such as typos or miscalculations, can significantly skew forecasting results. Regular data audits and validation techniques should be employed to identify and rectify these issues promptly. In addition, ensuring the timeliness of data is crucial; outdated data can misinform forecasts. Companies should integrate ongoing data collection approaches that capture real-time sales and inventory levels, maintaining an updated dataset for analysis. Furthermore, the context in which data is collected plays an essential role, as promotional events, holidays, or economic shifts can influence customer behavior in significant ways. To enhance forecasting processes, businesses can utilize data enrichment techniques. This may involve linking historical data with external datasets to gain broader insights into market trends and consumer preferences. Improving data quality enables companies to make better predictions, resulting in enhanced inventory management and improved customer experiences.

Statistical methods are key to analyzing historical data effectively. Techniques such as moving averages, exponential smoothing, and causal models are widely utilized in forecasting practices. The choice of model often depends on the nature of the data and the specific forecasting context. For instance, moving averages work well for stable, consistent data. Meanwhile, exponential smoothing is particularly effective for data exhibiting trends and seasonal variations. Companies should evaluate various statistical methods to identify the most appropriate for their needs. Moreover, it’s crucial to regularly validate these models against actual performance, enabling continuous improvement in forecasting accuracy. By incorporating advanced analytics, businesses can enhance their predictive capabilities. Machine learning algorithms offer powerful tools for processing large volumes of data and identifying complex patterns that traditional methods may overlook. These algorithms can dynamically adapt to changing conditions, improving their effectiveness over time. However, it’s important to note that machine learning also requires high-quality data for optimal performance. Businesses should invest in proper infrastructure and expertise to leverage these advanced techniques effectively. As a result, organizations will become more agile and responsive to market changes, ultimately leading to better demand forecasting outcomes.

Collaborative Efforts in Forecasting

Collaboration across departments is essential for accurate demand forecasting. Engaging sales, marketing, and operations teams allows businesses to gather diverse insights that inform forecasts. Each department can contribute unique perspectives based on customer interactions, market conditions, and operational capabilities. For example, sales teams may provide valuable information on customer preferences, allowing for adjustments in forecasting based on anticipated sales trends. Marketing teams can offer insights into upcoming promotions or campaigns, ensuring they are considered in the forecasting process. Such collaboration fosters alignment and encourages shared accountability in achieving demand goals. Implementing collaborative forecasting platforms can streamline communication and data sharing among teams. Encouraging regular meetings and discussions about forecasts allows departments to update their insights and review changes in demand indicators promptly. This collaborative structure creates an environment where all departments work together towards a common objective, ultimately improving forecast accuracy. Moreover, involving suppliers in the forecasting process can enhance overall supply chain performance. Suppliers can provide insights into production capabilities, lead times, and inventory levels, facilitating better-fitted forecasts that account for real-world constraints.

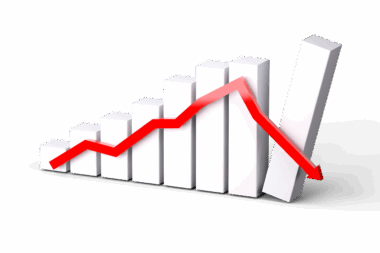

Beyond historical data, scenario planning plays an integral role in demand forecasting. By assessing various potential scenarios, businesses can better prepare for uncertainties that affect demand. An effective scenario planning process involves envisioning different market conditions, such as economic downturns or supply chain interruptions, and analyzing their impact on demand. Companies can use past experiences, insights, and market intelligence to construct these scenarios. Developing flexible forecasting models to accommodate different scenarios allows organizations to adapt quickly to unforeseen events. In addition, scenario analysis promotes business continuity by enabling companies to identify key risk factors that may disrupt their operations. By preparing for potential challenges, firms can create contingency plans to adjust their strategies proactively. These plans can encompass diversifying supply sources, changing pricing strategies, or increasing marketing efforts during specific periods. Moreover, continuous monitoring of demand metrics will allow organizations to recalibrate forecasts based on real-time information. Ultimately, combining historical data with scenario planning positions companies to respond effectively to the complexities of demand dynamics, reducing risks and enhancing resilience in supply chain management.

Leveraging Technology in Forecasting

Technology is a vital enabler in the realm of demand forecasting. Cloud computing, big data analytics, and artificial intelligence are transforming how organizations handle forecasting processes. These technologies offered greater computational power and storage capabilities, facilitating the analysis of larger datasets than ever before. Companies can leverage advanced analytics platforms to mine insights from historical data, customer behavior, and market trends. Moreover, machine learning algorithms enable businesses to analyze historical data patterns with impressive accuracy. Automation tools streamline data collection, aggregating information from various sources seamlessly. By reducing manual tasks, companies can dedicate valuable resources and time to strategy development instead of administrative functions. Furthermore, visualization tools allow teams to interpret complex data effectively, presenting insights through dashboards and intuitive displays. This fosters data-driven decision-making across departments, ultimately improving forecasting outcomes. Integrating technology into forecasting processes does come with challenges, such as the need to train staff on new systems or address potential data security concerns. However, the benefits of leveraging technology for demand forecasting are undeniable. Firms that embrace these innovations stand to enhance forecasting accuracy, create efficiency, and strengthen their competitive edge.

In conclusion, utilizing historical data for demand forecasting is indispensable for effective supply chain management. By collecting high-quality data and employing advanced statistical methods, organizations can derive accurate forecasts. Fostering collaboration among departments ensures a holistic approach, while scenario planning elevates adaptability to changing market conditions. The integration of technology plays a crucial role in streamlining processes and enhancing analytical capabilities. Ultimately, companies that prioritize data-driven decision-making in their demand forecasting efforts can achieve significant business benefits. Accurate forecasts lead to optimized inventory levels, improved customer satisfaction, and strengthened overall supply chain performance. As market dynamics continue to evolve, being agile and responsive will be essential for maintaining competitiveness. Companies should continuously invest in refining their forecasting techniques and embrace technological advancements to stay ahead of the curve. They must also remain vigilant in monitoring performance to refine their strategies as needed. By nurturing a culture of collaboration and data utilization, organizations can effectively respond to customer needs, fulfilling demands accurately and efficiently. The journey toward precision in demand forecasting is ongoing; businesses that remain committed to improvement will undoubtedly reap the rewards.