Inventory Turnover and Its Influence on Ordering Policies

Inventory turnover is a useful measurement for businesses. It denotes how often their stock is sold and replaced within a specific timeframe. A higher turnover rate suggests a business effectively sells its inventory, reducing storage costs and minimizing waste from unsold products. Conversely, a low turnover indicates potential problems in sales or overstocking. Analysts evaluate turnover in relation to industry benchmarks. The turnover ratio is calculated by dividing the cost of goods sold by average inventory during a period. This simple formula provides crucial insights into inventory management efficiency. Companies adept at managing their turnover often enjoy improved cash flow. High turnover can imply that businesses can reinvest their income quickly, driving growth. Additionally, competitive positioning is enhanced when products are consistently available for customers. Hence, understanding turnover shapes ordering policies. It aids businesses in forecasting demand accurately, ensuring they keep optimal stock levels. Managers can thus make informed decisions about when to reorder. Achieving the right balance is critical to sustaining operational efficiency while meeting consumer demands. Effective inventory practices also play a vital role in supply chain management, enabling agility and responsiveness in the marketplace.

Incorporating effective inventory turnover strategies leads to significant advantages. One of these benefits is minimized holding costs. High turnover rates mean that products remain in storage for shorter durations. This reduced time directly decreases expenses associated with warehousing, insurance, and handling. In contrast, products with low turnover can tie up capital, leading to diminished liquidity. Hence, firms nearby maximize financial resources. Moreover, optimizing turnover can enhance customer satisfaction. Regular stock rotation ensures that customers find fresh and high-quality items. Outdated or expired products create dissatisfaction and tarnish a brand’s reputation. Thus, businesses should continually assess their turnover metrics. This assessment allows for adjustments in ordering policies based on sales trends. Seasonal demand variations also necessitate flexible inventory approaches. During peak seasons, businesses may need to increase their stock levels to meet customer expectations. Strategic planning surrounding ordering can, therefore, drive sales growth while safeguarding brand integrity. Automatic inventory systems can support managers in monitoring turnover and making real-time decisions. Simplified processes facilitate timely reordering. Additionally, leveraging technology to analyze sales patterns increases responsiveness, ensuring companies remain competitive and adaptable in a changing market landscape.

Challenges in Inventory Turnover Management

While inventory turnover provides useful insights, managing it can be challenging. Businesses face several obstacles that may hinder effective turnover rates. One common challenge is inaccurate forecasting. If a company fails to understand its market demand, it may either overorder or underorder products. These discrepancies lead to strained liquidity or missed sales opportunities. Precise inventory management should involve constant market analysis to anticipate fluctuations accurately. Furthermore, longer lead times from suppliers can complicate timely stock replenishments. Supply chain delays diminish a company’s ability to maintain optimal turnover ratios. Companies must collaborate deeply with suppliers to enhance reliability and responsiveness. Another challenge is balancing stock variety. A wide assortment attracts varied customers, but it also complicates inventory management significantly. Striking the right balance between variety and maintainable turnover becomes essential. Companies can also struggle with technological integration. Transitioning to automated tracking and analysis systems requires investment and training efforts. Without proper systems, businesses risk continued operational inefficiencies. Continuous assessment of these challenges leads to more informed decision-making. Reviewing turnover metrics periodically helps identify issues, enabling timely adjustments before major losses occur.

Data-driven decision-making is paramount in optimizing inventory turnover. Using comprehensive analytics enhances a company’s ability to understand purchasing habits. Techniques such as predictive analysis allow firms to anticipate demand trends. This data-driven approach can inform strategic ordering policies that align with consumer needs. Furthermore, employing enterprise resource planning (ERP) software simplifies the analytical process. Effective ERP systems integrate all relevant data, offering a unified view of inventory. This insight facilitates more informed decisions on stock levels and reordering processes. Regular training for staff on utilizing analytics tools fosters a culture of excellence. Employees who understand inventory metrics are empowered to make crucial decisions regarding order placements and inventory management. Staff engagement can lead to innovative solutions that enhance inventory turnover approaches. Continuous investment in training further ensures adaptability to new technologies and practices. Adapting to demands in real-time allows companies to stay relevant and competitive. An operations-oriented mindset across departments can significantly improve overall effectiveness. Boosting engagement levels enhances teamwork while achieving shared objectives rooted in maintaining sound inventory practices. Proactive involvement leads to optimization that positively impacts the business’s bottom line.

Inventory Turnover Ratios and Industry Standards

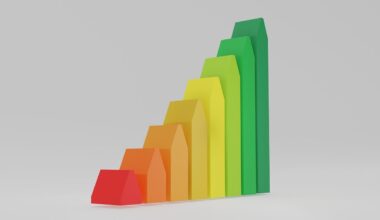

Understanding industry standards for inventory turnover ratios is essential for businesses. Each sector experiences unique selling patterns, affecting its average turnover rates. As a result, companies must refer to industry benchmarks for comparative analysis. Retail industries typically have higher turnover rates than manufacturers. For instance, grocery stores often exceed inventory turnover ratios of 10, while automotive manufacturers may exhibit a turnover rate closer to 6. This difference reflects the varied nature of product lifecycles. Consequently, firms should tailor their internal goals according to recognized industry standards. A higher-than-average turnover may indicate robust sales and customer demand. However, setting unrealistically high turnover goals can also prompt stock shortages, displeasing consumers and damaging brand perception. Firms should seek a balanced approach focused on sustainable ordering strategies. Regularly comparing internal inventory metrics with industry averages reveals performance issues. Companies below standard ratios can analyze their practices, pinpoint inefficiencies, and realign their operational strategies accordingly. Achieving optimal turnover fosters an environment conducive to growth and customer loyalty. Consequently, investors also recognize the value of effective inventory management strategies when assessing a company’s financial health.

Another crucial factor influenced by inventory turnover is supplier relationships. Businesses with high turnover often foster stronger collaborations with suppliers. This advantage stems from consistent ordering volumes and predictable purchasing patterns. Suppliers appreciate clients who maintain steady sales and are consequently more responsive to their needs. Improved communication builds strategic partnerships, fostering greater efficiency in the supply chain. Additionally, companies should invest time in evaluating potential suppliers. Practicing effective supplier evaluation leads to informed decisions that influence turnover. Supplier reliability directly affects inventory turnover; firms should partner with those who prioritize timely delivery and quality assurance. In turn, this reliability secures consistent product availability, ultimately enhancing customer satisfaction. Developing these relationships involves open dialogues about expectations and performance metrics. Furthermore, firms can explore alternate sources for critical items. Having multiple suppliers mitigates risks associated with stock shortages. Ultimately, strong relationships with suppliers support businesses’ ability to adapt to changing demands swiftly. As a result, securing a reliable supplier network can help bolster overall inventory turnover. When companies commit to nurturing these collaborations, they lay the groundwork for greater resilience and operational success. Thus, investing in supplier relations is essential.

Conclusion on Inventory Turnover Impact

In conclusion, understanding inventory turnover plays a vital role in shaping successful ordering policies. Companies that effectively manage their inventory turnover not only optimize their operations but also enhance customer satisfaction and brand loyalty. Strong inventory turnover boosts cash flow and minimizes holding costs, essential for financial health. Businesses can leverage technological advancements to improve forecasting accuracy and streamline their ordering processes. By employing data-driven strategies, companies can anticipate market trends, ensuring they meet customer demands. Furthermore, organizations must navigate the challenges associated with maintaining optimal turnover rates. Through continuous analysis, they can identify persistent issues and make timely adjustments. Setting realistic turnover goals aligned with industry benchmarks is key for sustained success. Firms should also recognize the importance of nurturing supplier relationships, enhancing collaboration and responsiveness. Ultimately, successful inventory management leads to improved operational efficiency and market competitiveness. Companies should remain agile, adapting their ordering policies based on data insights and changing market conditions. This commitment to excellence fosters a culture of innovation, driving growth in today’s competitive business landscape. Prioritizing inventory turnover effectively paves the way for operational achievements and sustained profitability.

To sum it all up, effective inventory turnover management is crucial for any organisation aiming to maintain a competitive edge. By focusing on optimizing turnover, businesses can enhance their operational efficiency and minimize costs. Moreover, the interplay between turnover rates and ordering policies ensures that companies meet consumer expectations consistently. Continuous investment in technology and analytics is vital in driving this optimization journey, enabling retailers and manufacturers alike to understand their inventory dynamics. Furthermore, collaborations with reliable suppliers create a robust supply chain framework that benefits everyone involved. A solid inventory strategy, informed by a comprehensive understanding of turnover, translates into better financial health and acuity in response to market changes. Ultimately, achieving and maintaining targeted turnarounds bolster confidence among investors, customers, and stakeholders alike. By employing best practices, supporting employee engagement, and leveraging technology, firms can create a sustainable competitive advantage. Companies should regularly evaluate their performance against industry benchmarks to ensure relevance in their market. They must combine intuitive insights with data analysis to adapt efficiently to changing demands. Prioritizing inventory turnover equips businesses with the resilience needed in today’s dynamic marketplace.