Emerging Technologies Shaping the Future of Manufacturing Automation

Manufacturing automation has seen a significant transformation over the decades, primarily driven by advancements in technology. The integration of robotics, AI, IoT, and machine learning systems has revolutionized the way manufacturing processes are carried out. Traditional methods are being increasingly replaced by advanced automated systems that enhance efficiency and reduce operational costs. In today’s competitive market, manufacturers are compelled to innovate constantly; they must adopt these emerging technologies to stay ahead. Robotics, in particular, has played a pivotal role in streamlining production tasks ranging from assembly to packaging. By leveraging these sophisticated machines, industries can achieve not only speed but also precision in their operations. Furthermore, incorporating Internet of Things (IoT) devices enables real-time monitoring and data collection, leading to improved decision-making processes. As manufacturing environments continue to evolve, the importance of adopting such advanced technologies cannot be overstated. In the face of today’s challenges, these automation tools provide vital solutions that help businesses thrive in ever-changing landscapes. The journey towards complete automation in manufacturing is both exciting and complex, but it promises various benefits for all stakeholders.

Artificial Intelligence (AI) is quickly becoming a cornerstone of modern manufacturing automation, enabling smarter processes. AI integration allows for predictive maintenance, which minimizes downtime, ultimately enhancing productivity. Through machine learning algorithms, production systems learn from past data to optimize performance in real-time. For instance, AI-driven analytics can make recommendations that significantly improve product quality and minimize waste. Moreover, AI technologies help predict equipment failures before they occur, allowing for proactive maintenance strategies. This not only saves costs but also enhances operational reliability. Additionally, intelligent systems can facilitate adaptive manufacturing processes, adjusting production based on demand forecasts. Such capabilities empower manufacturers to respond swiftly to market changes, ensuring they remain competitive. Coupled with AI, advanced robotics autonomously perform tasks that would typically require human intervention. The collaboration between humans and machines, also known as cobots, has redefined workforce dynamics in manufacturing. Companies are investing in training workers to work alongside these intelligent systems, which enhances overall productivity. These shifts towards integrating artificial intelligence into manufacturing automation present a bright future for industries looking to innovate and streamline their operations.

The Role of the Internet of Things in Automation

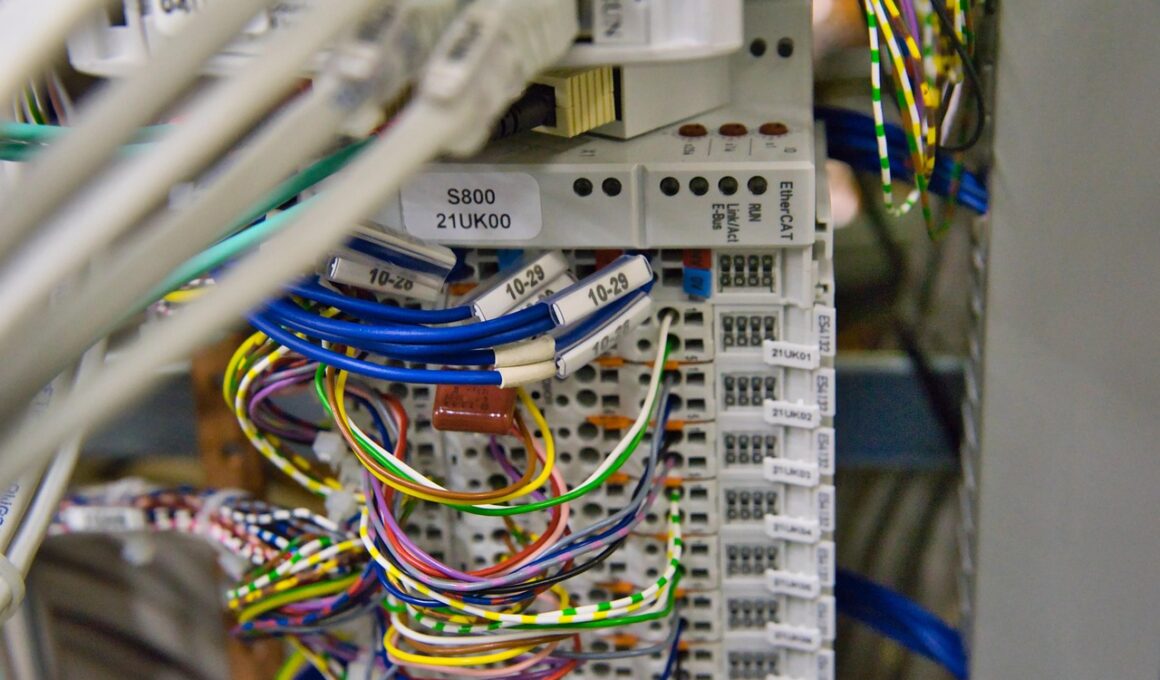

The Internet of Things (IoT) is another critical technology shaping manufacturing automation. IoT refers to the interconnected network of devices that communicate and share data seamlessly. In manufacturing environments, IoT sensors monitor equipment performance, collect data, and provide insights into operational efficiencies. This connectivity enables manufacturers to gain valuable insights into production processes, facilitating real-time decision-making. With the ability to analyze vast amounts of data, companies can identify trends and implement continuous improvements effectively. Furthermore, predictive analytics can be employed to foresee potential malfunctions and address them proactively. As a result, manufacturers can significantly reduce downtime and maintain high production levels. IoT devices also help in enhancing supply chain operations by providing visibility into logistics and inventory management. This visibility allows manufacturers to optimize resource allocation, reducing waste and ensuring timely deliveries. Additionally, the integration of smart technology leads to improved safety measures as potential hazards can be identified early through monitoring systems. The future of manufacturing automation relies heavily on the capabilities of IoT to create smart factories, ensuring increased efficiency and adaptability.

Moreover, the deployment of advanced data analytics within manufacturing automation systems offers unprecedented insights into operations. By analyzing data collected from various sources such as sensors, machines, and production lines, companies can uncover patterns and identify areas for improvement. This analytical approach leads to more informed decision-making, enabling manufacturers to streamline their processes effectively. Advanced analytics can also help in optimizing supply chain management by predicting customer demands and adjusting production schedules accordingly. This ensures that manufacturers meet market demands while minimizing excess inventory. Additionally, businesses can utilize data analytics to enhance quality control, as real-time data enables immediate detection of anomalies or defects in production. Through this data-driven approach, companies can foster a culture of continuous improvement, promoting innovation at every level of the organization. Furthermore, leveraging cloud computing provides the necessary infrastructure for storing and analyzing large datasets. This technology empowers manufacturers to access critical information from anywhere in real-time, leading to improved collaboration and strategy alignment across teams. As manufacturers embrace data analytics, they create a more agile and responsive operational framework, setting themselves up for long-term success.

Robotics: The Evolution of Automation

Robotics in manufacturing automation continues to evolve with modern capabilities that enhance productivity and safety. Collaborative robots or cobots are designed to work alongside human operators, augmenting their capabilities and supporting complex tasks. Unlike traditional industrial robots that often operate in isolation or require safety cages, cobots are equipped with advanced sensing technology to ensure safe interaction with humans. This innovative approach allows manufacturers to unlock the potential of automation without sacrificing workforce jobs. Cobots can be employed for repetitive tasks, such as assembly or sorting, freeing human operators for more skilled activities. In this way, the integration of robotics fosters a more efficient workflow that leads to improved outcomes and job satisfaction. Additionally, advancements in AI and machine learning empower these robots to learn from experiences and adapt their functions accordingly. Furthermore, deploying robotics significantly reduces the time required for product assembly and minimizes errors. This practice results in a faster turnaround time, benefiting the overall supply chain. As robotics technology continues to advance, the future of manufacturing is set to include even greater collaboration between human workers and automated systems.

Emerging technologies such as Virtual Reality (VR) and Augmented Reality (AR) are gaining traction in the manufacturing sector to improve training and operational efficiency. VR enables immersive training experiences for workers, allowing them to simulate real-life scenarios without the risks associated with traditional training methods. This immersive approach enhances the learning curve and helps employees build confidence in their roles. Additionally, AR provides real-time information and guidance during assembly processes, reducing the chances of errors. For example, technicians can use AR glasses to view crucial information overlaying the machinery they are working on, facilitating quick reference and problem resolution. This interactive hands-on approach significantly aids productivity and efficiency, ultimately leading to smoother operations. Furthermore, manufacturers leveraging VR and AR technologies can reduce the time and costs associated with employee onboarding and skill development initiatives. These technologies also promote a culture of innovation, as they encourage teams to explore and experiment with new processes. As manufacturers increasingly adopt VR and AR, they are likely to see a marked improvement in operational performance and employee engagement that drives success.

Conclusion: The Future of Manufacturing Automation

In conclusion, the future of manufacturing automation stands at an exciting crossroads, driven by emerging technologies that promise to transform the industry. Robotics, artificial intelligence, and IoT are not just buzzwords; they are reshaping how products are designed, developed, and delivered. The seamless integration of these technologies leads to smarter decisions and increased operational efficiency. Manufacturers adopting these innovations are better positioned to compete in the global market, maximizing productivity while minimizing operational costs. Moreover, the focus on collaboration between humans and machines fosters a more skilled workforce prepared for the challenges ahead. Continuous advancements in analytics and data-driven approaches are likely to provide further insights that refine production processes and drive continuous improvement. As the industry embraces the digital transformation journey, key challenges such as cybersecurity and workforce adaptation must be addressed to fully tap into the potential of these technologies. Ultimately, it is clear that manufacturing automation will continue to evolve as a pivotal aspect of modern production landscapes, leading industries into an era marked by innovation and excellence.