The Influence of Operational Budgeting on Supply Chain Management

Operational budgeting plays a significant role in shaping supply chain management processes. By offering a clear financial picture, it helps organizations allocate resources more effectively. In operations, budgets influence how supply chain activities are planned and executed. A well-structured operational budget enables businesses to forecast expenses accurately while identifying potential revenues. This strategic approach to budgeting can illuminate pathways for optimizing inventory levels and identifying inefficiencies. Consequently, successful budgeting can lead to reductions in operational costs and enhances profitability across the supply chain. When stakeholders understand the financial implications of decisions, they are empowered to make informed choices that align with broader organizational goals. Teams can prioritize investments in technology that improve operational efficiencies and enhance communication across the supply chain. Ultimately, operational budgeting can create an environment where costs are managed and savings are maximized. As businesses continue to navigate fluctuating market demands and supply chain disruptions, effective budgeting becomes a cornerstone for sustained operational success. Proactive budget management ensures that organizations can adapt and respond to changes, maintaining competitive advantages while fostering economic growth.

Furthermore, operational budgeting provides a foundation for performance measurement within supply chain management. By establishing clear financial metrics, organizations can assess their operational efficiency over time. This financial visibility allows for the evaluation of various supply chain activities, enabling businesses to track spending and identify areas for improvement. Key performance indicators (KPIs) driven by budgetary constraints help measure performance against set goals. Managers can analyze variances between projected and actual expenses, providing insights into decision-making processes. These analyses not only clarify financial outcomes but also inform future budgeting strategies. Additionally, aligning budgetary priorities with operational goals fosters accountability among team members regarding their performance. When each department knows its budgetary limits, it encourages fiscally responsible behaviors throughout the organization. Moreover, regular budget reviews ensure expenses remain in line with expectations while recognizing any unexpected costs or savings. By embracing this disciplined approach, companies can make timely adjustments that reflect the dynamic nature of supply chain operations. This adaptability is crucial in today’s fast-paced global market, where businesses must swiftly respond to ever-evolving demands and competitive pressures.

Strategic Resource Allocation

One of the prime advantages of effective operational budgeting lies in strategic resource allocation within the supply chain. A comprehensive budget plan identifies critical areas needing investment and underpins decision-making processes for resource distribution. When functions like logistics, procurement, and warehousing operate under a carefully outlined budget, opportunities arise for maximizing efficiency. Additionally, budget-driven initiatives can direct investments toward technologies that enhance supply chain responsiveness. For example, robust forecasting tools, inventory management systems, and supplier collaboration platforms may often warrant funding that contributes to smoother operational flows. Operational budgeting enables organizations to allocate resources towards streamlining processes and reducing delays, thereby improving customer satisfaction. Furthermore, when budgets align with strategic objectives, organizations can prioritize actions directly linked to their overarching vision. This thematic approach ensures a cohesive supply chain strategy is in place, which is responsive to market trends and consumer needs. Additionally, by continually assessing budget performance, organizations can rest assured that resources are allocated efficiently, ultimately boosting overall productivity. This precision in resource allocation drives sustainability in supply chain management and fosters long-term growth within the industry.

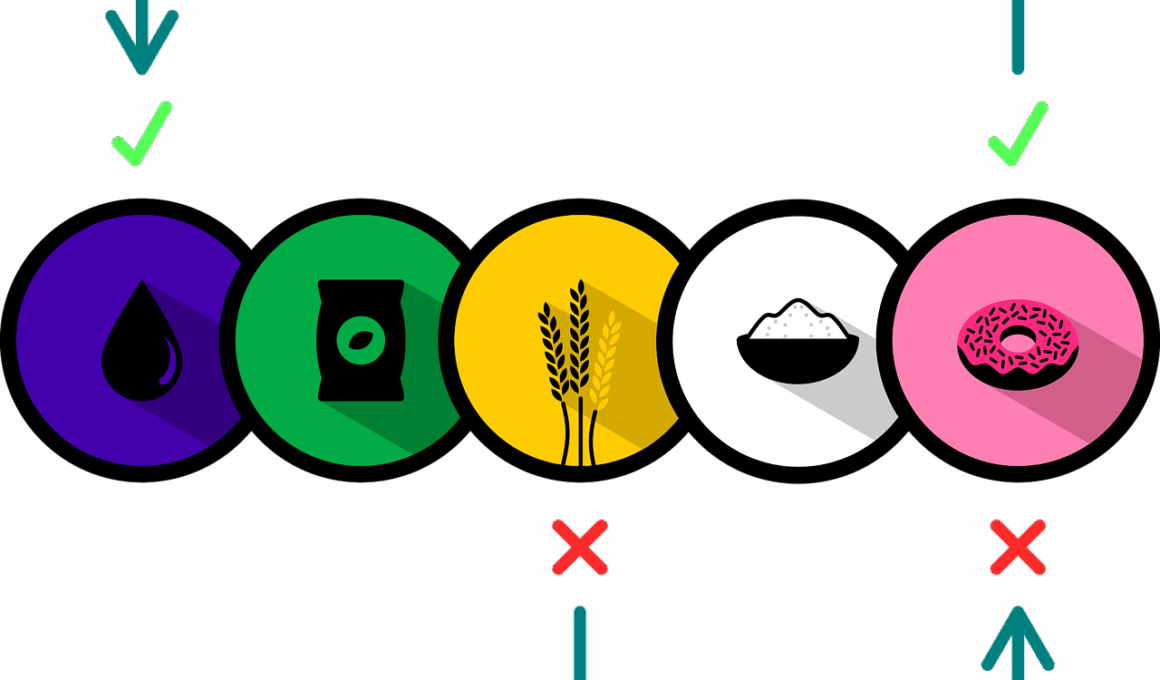

Another critical aspect of operational budgeting revolves around inventory management strategies. Effective budgeting directly impacts how inventory levels are maintained throughout the supply chain. Companies can analyze purchasing habits, sales forecasts, and stock levels to create budgets that reflect their operational realities. With insights drawn from these analyses, firms can implement Just-In-Time (JIT) inventory systems that minimize excess stock and associated holding costs. JIT strategies rely heavily on accurate budgeting to predict when to procure and replenish inventory to meet customer demand reliably. This approach helps eliminate waste and fosters efficiency as resources are invested precisely when needed. Moreover, operational budgeting empowers supply chain managers to adapt quickly to changing market conditions. For example, when seasonal fluctuations occur, budgets allow managers to plan accordingly for inventory bursts or reductions. By establishing clear triggers based on budget limits, organizations can avoid over-committing resources and ensure they stay agile. This agility is essential for maintaining competitive advantages in a constantly shifting economic landscape. Overall, an organized approach to budgeting leads to improved inventory control that aligns perfectly with demand and operational efficiency goals.

Risk Management and Mitigation

Operational budgeting also serves as a crucial tool for risk management within supply chains. By forecasting potential uncertainties and allocating funds for contingencies, organizations can develop robust strategies to mitigate risk. Budgets enable businesses to prepare for sudden shifts in demand, supply shortages, and market volatility. By incorporating risk assessment into operational budgeting, stakeholders can identify and prioritize risks that threaten supply chain stability. This proactive approach allows companies to allocate resources to potential disruptors, creating buffer zones that sustain operations during turbulence. Furthermore, understanding budget implications empowers teams to analyze trade-offs in their operational decisions. With financial visibility, organizations can adopt a risk-aware mindset when executing supply chain strategies. For instance, they can decide whether investing in multiple suppliers or enhancing inventory buffers is justified based on their budget constraints. Furthermore, budgeting can embed financial discipline into risk management processes ensuring a well-prepared organization. This disciplined financial approach helps optimize risk-taking while securing the resilience essential for continuous operational success. Effective risk management through operational budgeting ultimately enhances organizational resilience and adaptability.

In addition to the above factors, continuous improvement initiatives benefit greatly from operational budgeting practices. Budgetary insights cultivate a culture where supply chain processes are regularly scrutinized and refined. Organizations can establish lean initiatives, underpinned by their financial capacity, leading to improved operational efficiencies. Regular budget reviews can foster dialogue surrounding potential improvements, pushing supply chain teams to innovate continuously. By examining past budget performances, organizations can discern trends, issues, and potential improvements that redefine their strategies. Furthermore, effective budgeting enables firms to embark on training and development programs essential for optimizing human capital within supply chains. Investing in employee skills translates into better performance and enhances team morale, which ultimately drives overall operational excellence. Moreover, collaboration across departments fosters a holistic view when aligning tactical initiatives. As teams understand the practical ramifications of their budget limitations, they become more motivated to innovate within their areas of influence. This focus on continuous improvement helps forward-thinking organizations thrive in increasingly competitive markets, ensuring enhanced customer satisfaction while achieving sustainability. As enterprises embrace a growth mindset, operational budgeting remains a cornerstone for fostering ongoing enhancements.

Conclusion

In conclusion, operational budgeting is pivotal in shaping supply chain management practices. By providing a structured approach for financial forecasting and resource allocation, it plays a crucial role in decision-making processes. Proper budgeting impacts inventory management, risk mitigation, and continuous improvement initiatives, establishing a robust operational framework. Organizations leveraging effective budgeting strategies are better prepared to navigate the complexities of supply chains while optimizing costs and ensuring efficiency. Another important benefit is that operational budgeting fosters alignment between employees and organizational goals. Furthermore, by creating participation opportunities for various stakeholders in budget discussions, companies can ensure endorsement and commitment toward budgetary objectives. This alignment enhances communication, transparency, and collaboration within teams, fortifying organizational culture. As supply chains continue to evolve in response to market dynamics, the significance of operational budgeting cannot be overstated. Embracing innovative budgeting practices will empower organizations to remain resilient and position them successfully in challenging environments. Thus, prioritizing sound operational budgeting practices is essential for securing a competitive edge in the ever-changing landscape of supply chain management.