Managing Chemical and Biological Risks in the Workplace

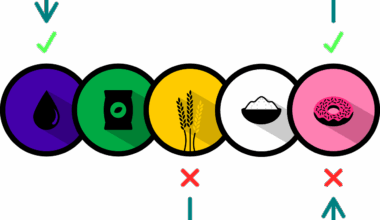

Effective health and safety risk management in workplaces dealing with chemical substances requires thorough preparation and strong commitment. These workplaces must identify hazardous chemicals and biological agents, assessing the level of risk they pose to employees. Just as importantly, employers need to maintain ongoing risk assessments, ensuring that any changes in procedures or substances are thoroughly evaluated. It is essential to educate employees about the potential risks they might encounter and to provide proper training on handling materials safely. Through comprehensive training programs, workers become equipped with the necessary skills and knowledge. Various regulations, such as the OSHA standards, outline legal requirements for managing risks associated with chemicals. Furthermore, effective labels and safety data sheets (SDS) play a vital role in risk communication, making it easier for employees to understand hazards and responses. Creating a culture of safety will encourage staff to communicate concerning any issues they observe regarding chemical safety. Ultimately, fostering a proactive approach to risk management contributes to the well-being and productivity of an organization, reducing incidents and creating a safer work environment for everyone.

In addition to workplace education and training, proper control measures are critical when managing chemicals and biological agents. Employers must implement safety measures such as engineering controls, administrative controls, and personal protective equipment (PPE). Engineering controls include installing adequate ventilation systems, fume hoods, or closed chemical systems to minimize exposure to harmful substances in the work environment. Administrative controls involve altering work practices, such as limiting the duration of exposure for employees or rotating assignments. Similarly, PPE, like gloves, goggles, or respirators, must be provided as necessary to protect employees from exposure. It’s vital that employers also foster an atmosphere where employees feel empowered to use PPE and raise safety concerns without fear. Regular maintenance of control equipment and training on new procedures is essential to ensure efficacy. Compliance audits can identify gaps in safety practices, providing opportunities for improvement. Establishing an incident reporting system fosters open communication, allowing employees to document and discuss any near misses or unsafe conditions. By prioritizing these control measures, workplaces minimize risks and ensure a safer working environment.

Risk Assessment Strategies

Regular risk assessments form the cornerstone of effective chemical and biological risk management. Employers should establish a systematic approach to evaluate risks regularly and systematically. Utilizing a hazard identification process enables organizations to pinpoint specific chemicals and biological agents at play within their facilities. By assessing the likelihood and severity of exposure, organizations can prioritize which risks require immediate attention and which permit longer-term solutions. In conducting risk assessments, it is crucial to consider factors such as frequency and duration of exposure, concentration levels of harmful substances, and protective measures currently in place. Employers can employ various methodologies for risk assessment, including qualitative and quantitative techniques. Engaging employees in the assessment process can yield invaluable insights since they are often the first to experience potential hazards. This collaborative approach ensures all perspectives are considered. Capturing assessment findings within a formal report outlines the identified risks and suggests action plans. Regularly reviewing and updating risk assessments ensures continuous improvement, fostering a workplace committed to health and safety.

The implementation of safety data sheets (SDS) plays an important role in managing risks associated with chemical and biological substances. These documents provide essential information regarding the identification, handling, and emergency procedures related to hazardous materials. Employers are required to ensure that SDS are accessible to all employees, empowering them to manage chemical exposure effectively. Understanding the information contained within these sheets allows workers to recognize hazards and exercise precautionary measures. It is necessary for employers to conduct regular reviews of their chemical inventory and ensure that SDS are current and applicable. Creating a centralized repository, whether digital or physical, makes it easier for employees to access required documents promptly. Additionally, responsible management of hazardous waste is critical to minimizing potential environmental and health risks. Establishing protocols for the safe disposal of expired or unneeded substances minimizes the chance of exposure for workers and nearby communities. Training employees on waste management can also enhance safety practices, promoting awareness of environmental issues, and engaging them in the full spectrum of health and safety management.

Emergency Preparedness and Response Plan

Emergency preparedness is crucial for managing chemical and biological risks in the workplace. Organizations must develop and maintain an effective emergency response plan that accounts for potential chemical spills, leaks, and other hazardous events. It is essential to identify potential emergency scenarios specific to the workplace environment, integrating employee roles and responsibilities into the action plans. Training all employees in understanding their roles during an emergency can significantly mitigate risks and ensure prompt and effective actions are taken. Regular drills, simulations, and reviews of emergency protocols will familiarize employees with procedures, ultimately enhancing preparedness. Businesses should also establish clear lines of communication for reporting emergencies and provide necessary resources, including first-aid kits and spill response kits. When incidents do transpire, thorough investigations should follow, aiming to determine root causes and enhance preventive measures. Cultivating an environment where continuous improvement is prioritized fosters a better safety culture driven by proactive solutions. Overall, workplace preparedness not only minimizes risks but also safeguards the lives of employees and the surrounding community in case of an emergency.

Continuous monitoring and evaluation of risks play a critical role in maintaining a safe work environment that prioritizes health and safety. Following the implementation of risk management strategies, organizations must establish metrics to assess the effectiveness of their programs. Conducting regular audits allows organizations to identify areas where policies may need enhancement or where compliance may wane. By adopting a feedback mechanism involving employee input, organizations can better understand the nuances of workplace safety. Additionally, technology-driven solutions, such as monitoring systems, can track chemical levels in real time, providing another layer of security and awareness. Investigating safety incidents further contributes to this approach, as analyzing events helps organizations learn about effective risk management practices. Progress must be shared transparently among staff, fostering a culture of trust and collaboration. By committing to continuous improvement in health and safety practices, employers demonstrate their dedication to safeguarding their employees, ultimately leading to enhanced productivity and lower costs associated with workplace accidents. This commitment to employee well-being translates directly into organizational success.

Conclusion: The Importance of Safety Culture

In conclusion, establishing a robust safety culture within the workplace is paramount in managing chemical and biological risks effectively. This culture should be fostered from the top down, encouraging all employees to take part in prioritizing safety measures. Explaining the significance of health and safety practices allows individuals to understand their role in creating a safer work environment. Management should lead by example, demonstrating a commitment to safety practices in everyday tasks. Employee engagement remains critical, as it cultivates ownership over safety protocols and encourages proactive reporting of hazards. Recognizing and rewarding positive safety behaviors reinforces the seriousness of health and safety initiatives. Moreover, sharing success stories can boost morale and encourage fealty to safety practices. Investing in continual training and improvement ensures that organizations remain capable of adapting to ever-evolving risks. As workplaces advance technologically, considerations for health and safety must evolve correspondingly. Ultimately, fostering a workplace committed to health and safety for chemicals and biological agents will lead not only to compliance but, more importantly, to protecting the most valuable asset of any organization—its employees.