Managing Supply Chain Compliance During Crisis Situations

In today’s globalized marketplace, effective supply chain compliance is crucial, especially during crisis situations. Events like natural disasters, pandemics, and geopolitical tensions can disrupt the flow of goods and services. Companies must swiftly adapt to these changes, ensuring compliance with relevant regulations. Organizations must develop a clear framework that incorporates necessary steps to maintain compliance. A comprehensive risk assessment is essential, allowing businesses to identify potential vulnerabilities within their supply chains. Establishing robust communication channels with suppliers and customers facilitates timely information sharing. Also, companies must regularly evaluate their compliance protocols to ensure they remain effective during adversity. Having contingency plans can help organizations respond promptly and effectively. Organizations should be well-versed in local, national, and international laws and regulations affecting their supply chains. Non-compliance can lead to hefty fines and damaged reputations, so staying informed and compliant is essential. Compliance training for employees ensures that everyone understands their responsibilities and the importance of adherence to regulations. Leveraging technology can assist in tracking and managing compliance efforts throughout the supply chain. Ultimately, effective management during crises can greatly alleviate potential supply chain disruptions.

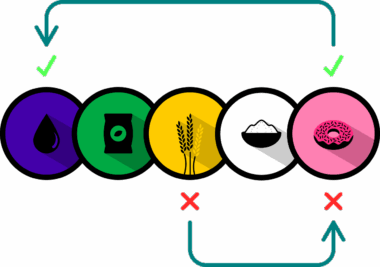

In addition to frameworks and assessments, companies must prioritize supply chain resilience. Resilience refers to the capacity to recover quickly from difficulties and adapt to changing circumstances. Businesses should incorporate flexibility into their supply chain operations. This involves diversifying suppliers and sourcing strategies to mitigate risks associated with reliance on a single source. Organizations can explore alternative transportation methods and multiple logistics partners to reduce vulnerability. Moreover, maintaining inventory buffers can help manage fluctuations in supply and demand. Implementing advanced data analytics and artificial intelligence can enhance predictive capabilities, allowing businesses to anticipate potential disruptions. Collaboration with suppliers and logistics partners is vital, fostering transparent relationships that encourage open communication about compliance challenges. Regular audits are necessary to maintain high compliance standards. Establishing compliance teams tasked with monitoring regulatory changes and evaluating risks ensures proactive management of supply chain compliance. Furthermore, documentation is critical; maintaining up-to-date records of compliance efforts assists in audits. Companies should adopt a mindset of continuous improvement, actively seeking strategies to enhance compliance protocols. Employees must be empowered to report potential compliance issues without fear. Nurturing a culture of compliance within the organization is essential for sustainable growth and operational integrity.

During crisis situations, rapid response capabilities can determine the outcome of supply chain compliance. Organizations must establish a crisis management team specifically focused on compliance issues. This team should consist of members who understand regulatory requirements, risk management, and supply chain dynamics. Implementing real-time monitoring systems will provide visibility into supply chain operations. This enables stakeholders to identify compliance breaches quickly and take corrective actions. Training employees in crisis response protocols ensures they are prepared to act decisively under pressure. Participation in simulations and scenario planning exercises can enhance an organization’s readiness. Open lines of communication with suppliers are vital, as they are crucial to maintaining compliance standards. Engaging in collaborative planning and problem-solving fosters resilience throughout the supply chain. Documentation plays a fundamental role during crises; having comprehensive records of compliance efforts ensures that companies can demonstrate adherence to regulations if questioned. Moreover, leveraging technology tools can streamline reporting processes. Companies should consider investing in compliance management software that offers real-time updates. These tools not only enhance compliance efforts but also save significant time and resources. Strong leadership commitment to compliance is essential during crises, as it sets the tone for the organization and inspires a collective response to challenges.

Adapting Compliance Strategies

Crisis situations necessitate an adaptive approach to compliance strategies, emphasizing flexibility and quick decision-making. Organizations can revise their compliance policies to mirror current realities while maintaining regulatory adherence. Conducting regular scenario analyses helps identify best practices and shortcomings in existing protocols. This knowledge allows for tailored amendments that meet evolving demands. Conversely, companies must remain wary of implementing temporary measures that could lead to unethical practices later. Lessons learned from previous crises should guide policy adjustments, incorporating historical context into new strategies. Engaging external compliance consultants can provide valuable insights into best practices prevalent in the industry. Furthermore, organizations should communicate policy changes to stakeholders promptly. Clarity in compliance expectations aids in minimizing confusion among employees, suppliers, and partners. Training programs can be updated to reflect new compliance standards, reinforcing the importance of adherence. Maintaining a feedback loop encourages all levels of staff to report challenges encountered during compliance. Recognizing the dynamic nature of supply chains fosters a proactive culture, preparing organizations for future crises. Building relationships with regulatory bodies can enhance trust and collaboration, offering further assurance during turbulent times. Ultimately, agencies and companies must work together to uphold compliance goals amid uncertainty.

Leveraging technology is indispensable for ensuring supply chain compliance in crisis situations. Digital transformation helps streamline compliance processes, providing companies with real-time oversight. Organizations can utilize automated systems to track compliance metrics, ensuring adherence to industry regulations. Cloud-based platforms allow for easier data sharing across various stakeholders, fostering collaboration within the supply chain. Incorporating blockchain technology adds an extra layer of security, enhancing traceability for supply chain transactions. Empowering employees with compliance-specific tracking tools promotes accountability and visibility into potential issues. Data analytics can reveal patterns that help organizations identify compliance risks before they escalate into crises. Furthermore, integrating artificial intelligence systems into compliance frameworks can enhance decision-making capabilities. AI algorithms can analyze vast amounts of data, flagging anomalies that indicate potential compliance breaches. Regularly updating digital tools according to changing regulations is vital to maintaining compliance integrity. Companies must also invest in IT infrastructure, enabling seamless adaptation to technological advancements. A successful technology strategy includes training employees to ensure they are comfortable utilizing new systems. Moreover, establishing a culture that embraces technology fosters an environment conducive to compliance excellence. The goal is to create a technology-driven compliance ecosystem that rapidly responds to crises while minimizing risks.

Supplier Collaboration and Compliance

Successful supply chain compliance during crises heavily relies on effective supplier collaboration. Establishing mutual trust and understanding with key suppliers is paramount. Companies should engage in regular discussions with suppliers to address compliance concerns proactively. This collaborative spirit extends to discussing alternative sourcing strategies during uncertain times. Ensuring that suppliers understand the critical nature of compliance enables organizations to work together in facing challenges. Joint compliance assessments can be beneficial as they offer insights into each partner’s capacities. Furthermore, fostering strong relationships can facilitate faster resolution of any compliance issues that arise. Contracts should clearly define compliance responsibilities while allowing for flexibility during crises. Ultimately, maintaining open lines of communication ensures that all stakeholders are on the same page when it comes to compliance expectations. Collaborating on compliance training initiatives can enhance knowledge-sharing between companies and suppliers, benefiting the entire supply chain. Building resilient supplier networks that can adapt to crises is vital. This includes diversifying the supply base to minimize risks associated with single points of failure. Partners who are willing to innovate in response to challenges create a competitive advantage. Adopting a strategic partnership approach ensures that companies remain compliant even during the most trying times.

Finally, evaluating supply chain compliance after crises provides invaluable insights for the future. Companies should conduct thorough post-crisis assessments to understand the effectiveness of their compliance strategies. Collecting feedback from employees, suppliers, and customers allows organizations to identify strengths and weaknesses in their compliance efforts. These evaluations guide ongoing improvement and reshaping of compliance frameworks. Establishing key performance indicators (KPIs) enables organizations to monitor compliance efficacy over time. Continuous monitoring helps maintain adherence to regulatory requirements even in fluctuating environments. Furthermore, documenting crisis responses and outcomes will contribute to a wealth of knowledge for future reference. This information serves as a guide during future adverse situations, enhancing organizational preparedness. Learning from past experiences is crucial, enabling teams to streamline procedures and develop best practices. Engaging with external experts to review compliance strategies can also provide fresh perspectives. Companies should also share their experiences within industry networks to foster collective growth. Ultimately, the commitment to improving compliance processes helps organizations navigate future crises more effectively. A culture of learning, transparency, and adaptation strengthens supply chain compliance capabilities across all levels.