Choosing the Right Automation Technology for Your Manufacturing Business

In today’s fast-paced manufacturing environment, selecting suitable automation technology is crucial for operational efficiency and profitability. With numerous options available, businesses often struggle to identify the best solutions tailored to their specific needs. Understanding the various types of automation technologies, their benefits, and the specific requirements of your manufacturing processes is paramount. This assessment allows businesses to enhance productivity, minimize waste, and streamline operations. Assessing your current production capabilities and future goals is essential before diving into the selection process. Key factors include evaluating existing equipment, workforce capabilities, and specific industry demands. Moreover, engaging with technology providers to discuss your challenges can yield valuable insights. This partnership facilitates a more informed decision regarding automation technology. Manufacturers should also consider scalability in their choices, ensuring the selected solutions can evolve with future trends and consumer demands. Another significant factor is the total cost of ownership, which involves understanding not just the initial investment, but also ongoing operational costs. Balancing these considerations enables businesses to implement automation technologies that not only meet current needs but also support future growth.

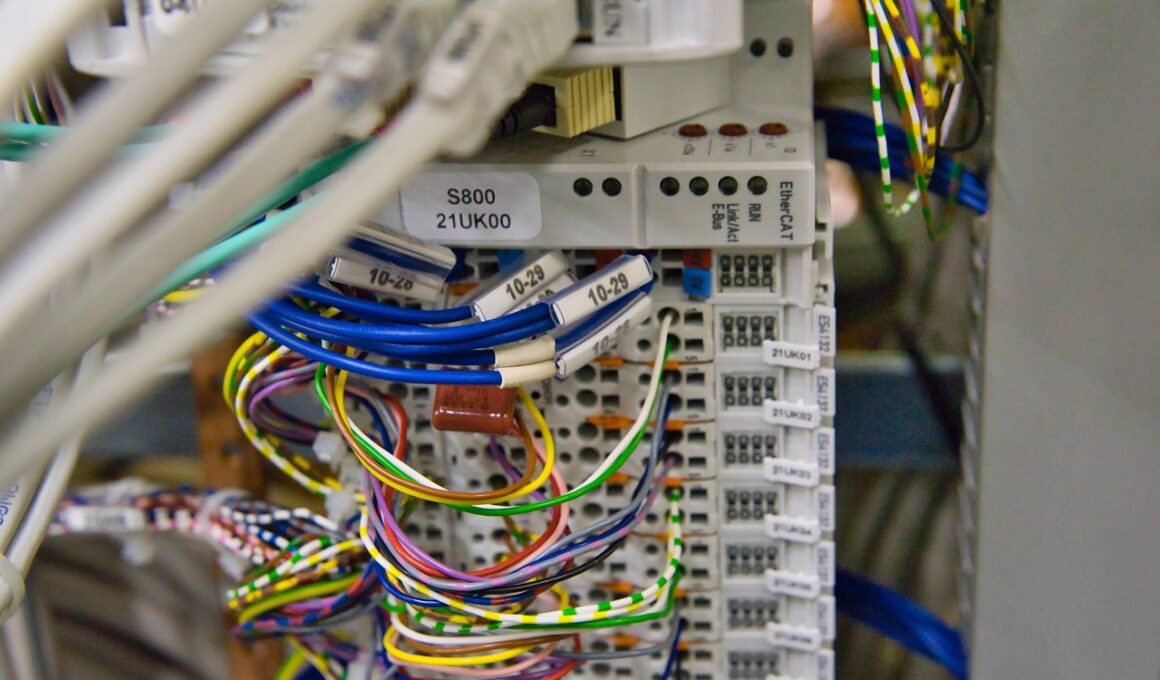

Understanding the different types of automation technologies available is vital for making informed decisions. Various options, such as fixed, programmable, and flexible automation systems, serve distinct functions in manufacturing processes. Fixed automation is suitable for high-volume production with repeatable tasks, while programmable automation offers versatility for batch production. On the other hand, flexible automation systems can adapt to different product designs, making them ideal for manufacturers needing to respond swiftly to market changes. Moreover, integrating robotics into manufacturing has become a game changer, enabling companies to achieve higher precision and efficiency. Robots can perform tasks that are repetitive and hazardous, leading to improved workplace safety. Alongside robotics, machine learning and artificial intelligence serve as powerful tools for data analysis and process optimization. Implementing these advanced technologies helps in predictive maintenance, reducing downtime and increasing operational efficiency. Investing in automation technology is not solely about immediate gains; it is also about long-term sustainability. Consequently, manufacturing leaders must align their technology choices with both current operational goals and long-term growth strategies,

Evaluating Your Manufacturing Processes

Before investing in automation technology, a thorough evaluation of your existing manufacturing processes is essential. Understanding workflows, bottlenecks, and areas of inefficiency can uncover opportunities for automation. Engaging employees in this evaluation can provide insights from the ground level, revealing practical challenges faced daily. Documenting these processes thoroughly helps identify repetitive tasks suitable for automation, primarily focusing on tasks that hinder productivity and increase labor costs. Additionally, an assessment of equipment capabilities and limitations is crucial in establishing what type of automation will complement or replace existing systems. Moreover, a comprehensive analysis of supply chain dynamics is necessary to determine how automation can improve coordination and speed. Considering the skill level of the workforce is equally vital, as some automation technologies require specialized knowledge. Investing in training programs for employees can enhance their capability to adapt to new systems. Ultimately, a well-rounded understanding of existing processes not only prepares the business for successful technology integration but also fosters a culture of continuous improvement.

Another critical aspect of selecting automation technology is analyzing return on investment (ROI). Manufacturers must consider initial costs, operational savings, and the time required to realize financial benefits. A robust ROI analysis helps businesses substantiate their investment decisions, as well as identify metrics to measure success post-implementation. Consulting with financial experts or automation providers can enhance this analysis, offering perspectives that may not be immediately noticeable to internal teams. There are numerous factors influencing ROI, such as increased production rates, reduced labor costs, and enhanced product quality. Furthermore, businesses should assess potential sales growth due to improved product offerings and market responsiveness, facilitating further revenue opportunities. In addition to financial metrics, it’s essential to consider qualitative benefits, which include workforce satisfaction and improved brand reputation. A satisfied workforce often leads to higher retention rates, reducing attrition costs. Moreover, enhanced product quality can improve customer satisfaction, leading to repeat business and positive word-of-mouth marketing. Understanding these various ROI elements ensures that manufacturing leaders can make comprehensive evaluations of their automation technology implementation.

Choosing Automation Vendors

After considering internal assessments and ROI analyses, the next step involves choosing the right automation vendors. Not all vendors offer the same levels of service, support, or expertise in specific industries. Identifying providers with a proven track record in manufacturing automation, especially within your sector, is vital for ensuring successful implementation. Engaging multiple vendors for discussions and demonstrations can provide insightful perspectives on their capabilities. Furthermore, seeking out customer references and testimonials can offer reassurance regarding the vendor’s reliability. It’s equally important to assess their commitment to customer support post-installation, as ongoing assistance is crucial for troubleshooting and optimization. Inquire about their training processes for your workforce; effective training can ease the transition and ensure that your team is competent in operating new systems. Additionally, considering each vendor’s reputation for innovation and responsiveness to market changes can provide insights into their compatibility with your long-term manufacturing goals. Ultimately, making a well-informed choice ensures your business deploys automation technology that aligns with operational strategies and enhances competitive edge.

Integration of automation systems within existing infrastructure signifies a crucial stage in the entire process. A well-organized integration plan must address how new technologies will work with existing equipment and systems in place. Disruption during this phase can lead to costly downtime, thus necessitating a carefully structured implementation strategy. Engaging with both internal teams and vendors to establish communication protocols is essential for a smooth transition. Conducting pilot tests before full-scale implementation allows manufacturers to identify potential issues early on and adapt strategies accordingly. Encouraging employee involvement during testing phases encourages a sense of ownership and further eases acceptance of new technologies. Moreover, it’s beneficial to schedule regular check-ins to evaluate the implementation’s progress and adjust as necessary. During this phase, monitoring metrics enables manufacturers to assess the performance of newly implemented systems against projected outcomes. Effective change management practices, such as providing ongoing support and resources, contribute positively to workforce adaptation. Emphasizing clear communication fosters a culture where employees feel valued and informed, paving the way for a successful transition toward enhanced automation in manufacturing operations.

Future of Automation in Manufacturing

Looking ahead, the future of automation in manufacturing is both promising and complex. As technologies continue to evolve, manufacturers must remain agile in adopting new innovations that enhance operational efficiency. The integration of advanced technologies such as artificial intelligence, Internet of Things (IoT), and blockchain is set to revolutionize the manufacturing landscape. These advanced technologies can facilitate real-time data analysis, predictive maintenance, and better supply chain transparency, which are vital for today’s competitive market. Continuous research and development efforts are essential to keep pace with innovations, creating a landscape where manufacturers can optimize their processes. Moreover, global market trends and shifts in consumer behavior necessitate an adaptable approach to automation solutions. Sustainability is emerging as a significant driver in manufacturing decisions; thus, businesses must factor environmental practices into their automation strategies. Embracing sustainable technologies not only aligns with consumer expectations but can also lead to operational cost savings. Manufacturing leaders should foster a culture of innovation, encouraging experimentation and collaboration, ultimately positioning their businesses for success in this rapidly changing environment.

In conclusion, making the right choices regarding automation technology in manufacturing requires comprehensive planning and awareness. A careful evaluation of existing processes and a clear understanding of how to leverage new technologies are vital for long-term success. By analyzing ROI in both quantitative and qualitative terms, businesses can ensure their investments are justified and effective. Partnering with reputable automation vendors provides invaluable support and expertise, ensuring proper implementation. Moreover, maintaining an adaptable approach to emerging technologies helps businesses stay ahead of competition while continuously improving product offerings. As the manufacturing landscape evolves, staying committed to innovation and efficiency will be essential for sustaining growth. The future lies in a balanced approach that weighs automation advancements with the uniqueness of individual business needs. Embracing these opportunities cultivates resilience and strength in an unpredictable market, ensuring that companies thrive amidst challenges. Ultimately, the right automation technology can transform manufacturing processes, resulting in enhanced productivity, safety, and profitability. The journey towards automation is an ongoing one, filled with opportunities for improvement, making it a strategic necessity for today’s businesses.