Demand Forecasting and Customer Satisfaction: A Link Explained

Demand forecasting plays a crucial role in supply chain management, directly impacting customer satisfaction. Accurate demand forecasts allow businesses to align their stock levels with customer needs, thus reducing excess inventory and stockouts. By predicting the demand trends, companies can optimize their inventory, ensuring that products are available when customers want them. This not only enhances customer satisfaction but also streamlines the supply chain, leading to cost savings. Additionally, the ability to anticipate customer demand ensures that production and distribution processes are more efficient. Collaborating with various stakeholders in the supply chain can further improve demand forecasting accuracy. Organizations leverage historical data and market analysis to refine their predictions continuously. Investments in technology, such as machine learning and data analytics, facilitate better forecasting accuracy. As such, understanding the relationship between demand forecasting and customer satisfaction is vital. When companies can address customer needs promptly and effectively through accurate forecasting, they build stronger consumer loyalty and trust. This ultimately results in a competitive advantage in the market, significantly impacting overall business performance. Given the importance of accuracy, organizations should prioritize enhancing their forecasting strategies to ensure lasting success.

The Role of Data in Demand Forecasting

Data is the backbone of accurate demand forecasting. Companies gather information from various sources, including sales history, market trends, and customer preferences to create reliable forecasts. The use of quantitative analytics helps organizations to identify patterns in consumer behavior, allowing for more refined predictions. Qualitative data, such as customer feedback and expert opinions, can also provide insights into potential demand shifts. Combining these data types leads to a more comprehensive understanding of market dynamics. Effective data management systems ensure that relevant information is easily accessible and interpretable for forecasting purposes. Furthermore, employing sophisticated analytics tools makes it easier for businesses to adjust their strategies based on real-time data. With continuous advancements in technology, companies now leverage big data technologies to analyze vast datasets quickly. Predictive modeling enables businesses to simulate various scenarios, adjusting forecasts accordingly. Ultimately, harnessing the power of data in demand forecasting solidifies the link between inventory management and customer satisfaction. Companies that effectively use data-driven insights are better equipped to meet customer expectations and respond promptly to market changes, sustaining their competitive edge.

The integration of advanced technologies significantly boosts demand forecasting capabilities. Tools like artificial intelligence and machine learning facilitate parsing through complex datasets, allowing companies to generate more precise forecasts. Machine learning algorithms can continuously learn from new data, improving their accuracy over time. This technological advancement enables organizations to anticipate shifts in demand patterns effectively. Moreover, real-time data integration offers businesses a dynamic approach, enabling instant adjustments to forecasts when market conditions change. This flexibility is vital in today’s fast-paced environment where consumer preferences may shift unexpectedly. As companies increase their reliance on technology for forecasting, those that adapt quickly can maintain customer satisfaction levels. The ability to forecast accurately enables businesses to transport the right products at the right time, thereby increasing their service levels. By investing in technology, companies not only enhance their forecasting precision but also streamline their operations. Consequently, a well-implemented digital framework will lead to shorter lead times and improved inventory turnover rates. This will not only satisfy current customers but also attract new ones through improved service offerings and reliability.

Collaboration Across the Supply Chain

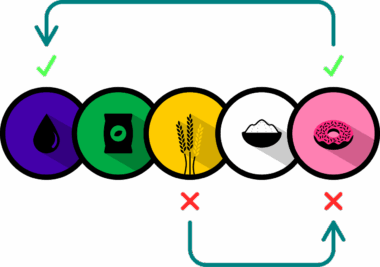

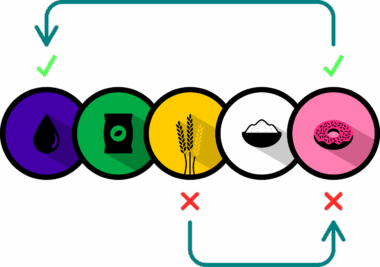

Collaboration with suppliers and partners is essential for enhancing the accuracy of demand forecasting. When organizations share data and insights across their supply chain, they can arrive at more reliable predictions. This collaborative approach fosters a more integrated system where changes in demand can be communicated effectively between stakeholders. Engaging suppliers in the forecasting process allows for a deeper understanding of production capabilities and lead times. Accurate demand forecasting requires a holistic view of the supply chain ecosystem. By leveraging collaborative technology platforms, businesses can synchronize their operations while enhancing transparency. This synchronization leads to minimized disruptions and responsive inventory management practices. Sharing forecasts with partners also cultivates mutual trust, fostering a more resilient supply chain. Additionally, improving communication between all participants helps in making quicker decisions based on the most current information. Organizations can use shared forecasts to optimize stock levels as well, reducing carrying costs. Overall, a collaborative approach in demand forecasting impacts customer service by ensuring optimal product availability. Addressing the changing needs of customers becomes easier when all members of the supply chain align their objectives toward common goals.

Customer satisfaction hinges significantly on how effectively companies can respond to demand fluctuations. Proper demand forecasting equips organizations to maintain product availability aligned with customer expectations. When businesses accurately predict consumer behavior, they can implement proactive strategies to meet those demands, enhancing the overall buying experience. Issues such as stockouts and excessive backorders frustrate customers, leading to dissatisfaction and diminished loyalty. On the contrary, organizations that successfully manage their inventory levels are better suited to deliver consistent service quality to their customers. This reliability results in a positive brand image, helping to attract new customers. Moreover, returning customers are often a reflection of excellent demand management. Satisfied customers are likely to share their experiences, benefiting the business through positive word-of-mouth referrals. Companies should regularly review their forecasting processes to adapt to evolving consumer trends. By incorporating customer feedback into the forecasting process, businesses can make more informed decisions. This responsive approach reinforces customer loyalty and satisfaction, contributing to long-term success. Combining customer-centric strategies with robust demand forecasting practices allows organizations to thrive in a competitive market landscape.

Challenges in Demand Forecasting

Despite the advantages of demand forecasting, several challenges can hinder effectiveness. Market volatility, shifting consumer preferences, and external economic factors can complicate accurate predictions. Businesses often struggle to interpret complex data, which may lead to flawed forecasts. Moreover, lack of reliable data sources can impede the forecasting process, leaving organizations with gaps in their understanding. Another critical challenge is the time it takes to gather and analyze data effectively. Rapid changes in the marketplace may render a forecast outdated before implementation. Companies need agile systems that can quickly adapt to these shifts. Furthermore, reliance on historical data alone may not always yield accurate insights, as consumer behavior is constantly evolving. To combat these challenges, organizations should invest in training staff on data interpretation and analysis. Implementing advanced analytics tools can empower teams to derive insights promptly. A continual review and adjustment strategy can also enhance forecasting reliability amid changing market conditions. By acknowledging and addressing these challenges, companies can pave the way for continuous improvement in their forecasting accuracy, ultimately benefiting customer satisfaction and operational efficiency.

In summary, the connection between demand forecasting and customer satisfaction is fundamental in supply chain management. Organizations that prioritize accurate forecasting can deliver on customer expectations, fostering loyalty and improving their profit margins. By utilizing comprehensive data analytics and collaboration with partners, companies stand a better chance of meeting fluctuating market demands. Additionally, technology plays a pivotal role in simplifying the process, ultimately allowing businesses to be more responsive and agile. Recognizing challenges and addressing them through training and technology investments further enables organizations to meet customer needs effectively. As the marketplace continues to change rapidly, maintaining a focus on improving forecasting accuracy will provide a sustainable competitive advantage. An effective approach to demand forecasting integrates customer insights, technology, and collaboration, allowing businesses to meet customer requirements consistently. Ultimately, the synergy between accurate demand forecasting and heightened customer satisfaction will drive growth in revenue and market share. For companies aiming to thrive in today’s competitive space, honing in on these aspects of supply chain management is crucial for long-term success.