Leveraging IoT for Continuous Monitoring of Automation Systems

In today’s fast-paced industrial landscape, leveraging the Internet of Things (IoT) for continuous monitoring of automation systems is becoming increasingly vital. IoT enables organizations to collect real-time data from various sensors and devices embedded in their systems. This data can significantly enhance decision-making processes, improve operational efficiency, and reduce downtime. For businesses aiming for streamlined operations, continuous monitoring ensures that potential issues are identified before they escalate. This leads to significant cost savings and operational resilience. Moreover, the integration of IoT technology not only boosts performance but also enhances quality control in production lines. Utilizing predictive analytics, organizations can foresee equipment failures and carry out timely maintenance strategies. This proactive approach prioritizes productivity while ensuring safety and compliance within workplaces. Therefore, IoT serves as a powerful tool to facilitate smarter, data-driven approaches in monitoring automation systems. By utilizing IoT, businesses can harness the capabilities of data analytics to respond promptly to challenges, thereby maintaining market competitiveness. In summary, adopting IoT for continuous monitoring transcends traditional methods, ushering in a new era of automation.

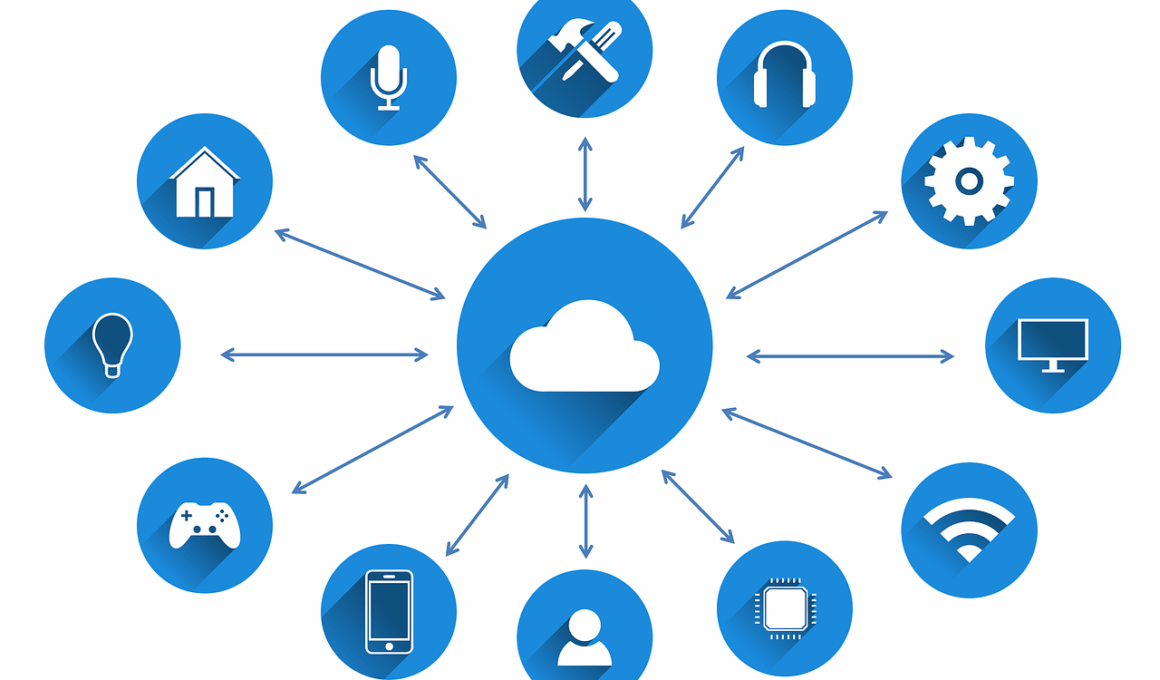

Understanding how IoT devices communicate within automation systems is crucial for effective monitoring. These devices leverage wireless technologies such as Wi-Fi, Bluetooth, and cellular networks to transmit data seamlessly. This real-time connectivity allows operators to receive alerts and notifications about system performance instantly. By integrating sophisticated monitoring platforms, organizations can visualize data comprehensively and derive actionable insights. Additionally, cloud computing plays a pivotal role in IoT functionality as it facilitates the storage and processing of vast amounts of data. Operators can access this information from anywhere, ensuring they stay informed about system status at all times. The scalability of IoT solutions further empowers businesses, allowing them to adapt easily as operational needs evolve or expand. Moreover, machine learning algorithms can analyze historical data to uncover patterns, thus optimizing maintenance schedules. As a result, businesses can enhance their responsiveness to potential disruptions and foster a culture of continuous improvement. Therefore, investment in the right tools and technologies is essential for realizing the full potential of IoT in automation system monitoring. This transition offers seamless integration with existing technologies and promotes efficiency across different operational levels.

Benefits of IoT Integration

Integrating IoT into automation systems offers numerous benefits that businesses cannot afford to overlook. First and foremost, cost reduction is a significant advantage. By implementing a continuous monitoring framework, facilities can avoid unexpected downtime, minimizing repair costs. Secondly, improved efficiency results from analyzing real-time data to optimize operational processes. Automation systems equipped with IoT capabilities can detect anomalies in performance, leading to prompt corrective action. Thirdly, enhancing safety standards is crucial for industrial environments; IoT technologies can monitor conditions that may pose risks to personnel. This includes detecting hazardous situations before they escalate into emergencies. Furthermore, compliance with regulatory standards is streamlined, as real-time monitoring provides necessary documentation. Additionally, higher product quality can be achieved through consistent monitoring and data analysis; issues are resolved while still in the production cycle. These benefits collectively contribute to improved customer satisfaction, which bolsters a company’s reputation. As businesses strive to innovate and maintain a competitive edge, the integration of IoT emerges as a strategic imperative. Overall, embracing this technology not only reformulates operational practices but also enhances market adaptability and growth trajectory.

However, implementing IoT for continuous monitoring is not without its challenges. Security remains a primary concern as interconnected devices are susceptible to cyber threats. Organizations must invest in robust cybersecurity measures to protect sensitive data and maintain system integrity. Additionally, the complexity of integrating IoT solutions with pre-existing systems can hinder smooth transitions. Businesses must perform adequate assessments to ensure compatibility and functionality across platforms. Furthermore, the sheer volume of data generated by IoT devices presents another obstacle; organizations must employ effective data management strategies. Ensuring that relevant data is captured and analyzed without overwhelming resources is vital. Equally important is fostering a culture of technological adaptability within the workforce; employees must be trained to utilize new systems effectively. Therefore, collaboration among stakeholders, including IT and operational teams, is essential to address these challenges. Thorough planning and strategic implementation are necessary for maximizing the return on investment in IoT technology. Overall, while challenges exist, the potential rewards of optimizing automation systems through IoT far outweigh the risks, making it an essential consideration for businesses today.

The Future of IoT in Automation

The future of IoT in monitoring automation systems looks promising as technology continues to evolve and integrate into everyday operations. As predictive analytics become more sophisticated, the ability to forecast issues will improve, allowing organizations to minimize interruptions significantly. The application of artificial intelligence (AI) within IoT environments further enhances proactive maintenance strategies. AI can process vast datasets and identify trends that human analysts might overlook, making it invaluable for decision-making. Moreover, the evolution of 5G technology is set to revolutionize IoT applications by increasing data transmission speeds and connectivity. This advancement will enable more devices to communicate simultaneously, allowing for even more comprehensive monitoring capabilities. Additionally, the advent of edge computing will support real-time processing closer to data sources, leading to quicker responses. Businesses that stay ahead of these trends will have the advantage of fully harnessing the capabilities of IoT in automation. Embracing these changes and remaining adaptable will prepare organizations for future disruptions. With the potential for innovation and excellence through IoT, the future of automation systems will be both efficient and intelligent.

In summary, leveraging IoT for continuous monitoring of automation systems entails significant advantages that can drive business success. From improved operational efficiency to enhanced safety and cost reduction, organizations can gain a competitive edge by adopting these technologies. The ability to capture real-time data not only facilitates quick decision-making but also fosters a culture of continuous improvement. While challenges such as cybersecurity and integration complexities exist, they are manageable with thorough planning and strategic implementation. As businesses continue to navigate a dynamic environment, the embrace of IoT technologies emerges as a serious consideration. This proactive approach contributes to resilience and innovation within organizations, empowering them to maintain relevance in their respective industries. Furthermore, as technological advancements continue, organizations must remain vigilant in recognizing and adapting to these changes. Therefore, continuous investment in IoT and related technologies will be critical for achieving operational excellence. Companies keen on advancing should actively seek partnerships with technology providers and invest in training for their workforce. Overall, as IoT reshapes the monitoring landscape, businesses must join the conversation to explore its vast potential for transforming automation systems.

Conclusion

To conclude, the integration of IoT into monitoring and maintaining automation systems is essential for modern business operations. This transformative technology not only enhances efficiency but also offers valuable insights for strategic planning. As industries evolve, the pressure to optimize processes continues to grow; IoT provides a necessary solution. By committing to continuous improvement and data-driven approaches, organizations can achieve operational excellence while reducing costs. The proactive maintenance strategies made possible through IoT minimize downtime, ensuring production schedules remain uninterrupted. Consequently, operational resilience is achieved, leading to long-term success. Moreover, as technology continues to advance, exploring new innovations within the IoT space can unlock untapped potential. Businesses must stay informed about trends and adapt accordingly to leverage these advancements effectively. Understanding the importance of cybersecurity, scalability, and integration will enable businesses to navigate any potential challenges ahead. With the right strategies and investment in IoT technologies, the future possibilities for automation systems are boundless. Lastly, organizations will pave their path towards growth and sustainability, remaining competitive in the global market.

By embracing IoT for continuous monitoring, organizations prepare themselves for the future while streamlining their current operations. This strategic shift offers not only the potential for immediate benefits but also ensures longevity in an ever-evolving business landscape. As the integration of technology continues to redefine industries, stakeholders must consider the role of IoT seriously. Future-proofing operations through this technology entails a commitment to innovation, training, and strategic partnerships. The rewards of improved efficiency, reduced costs, and enhanced safety are compelling reasons for businesses to take action. Furthermore, active engagement in ongoing research helps understand and apply the latest advancements in IoT. By positioning themselves for success, organizations can maximize the potential of their automation systems. Ultimately, this collective effort facilitates a culture that values data-driven insights and embraces continuous improvement. As businesses navigate turbulent waters, the knowledge and resources accumulated through IoT adoption will serve as a guiding light, leading them towards operational excellence and increased profitability.